Unlocking operational excellence in your control room is now easier than ever with FAT FINGER. This digital workflow procedure builder allows you to create custom checklists, workflows, and digital procedures that streamline your operations. In this article, we will delve into the features of FAT FINGER and how they provide a solution for developing custom control room monitoring workflows.

Ready to revolutionize your control room operations? Request a demo today.

Understanding FAT FINGER

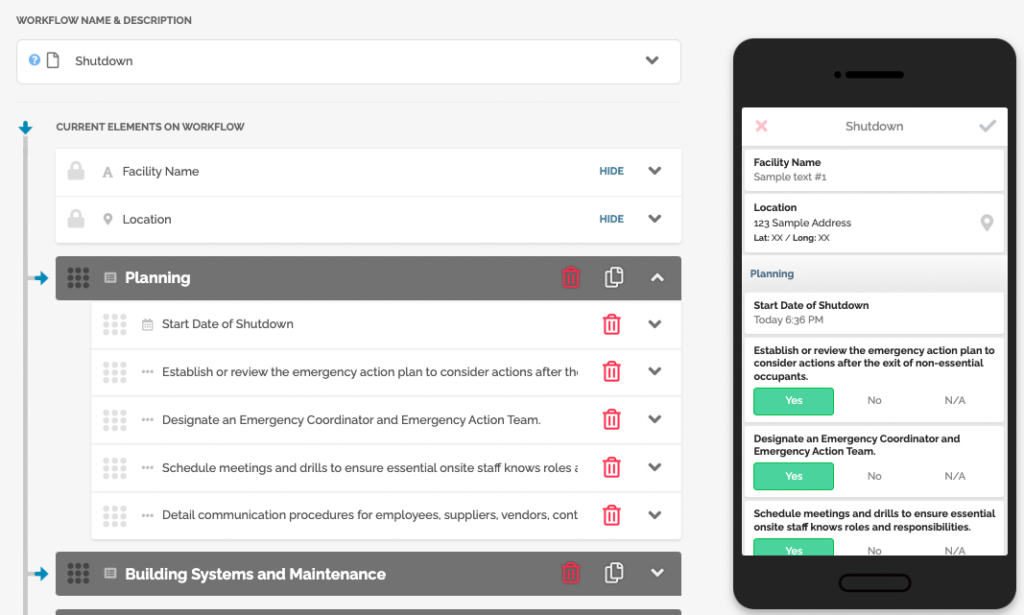

FAT FINGER is a cutting-edge software designed to simplify and optimize your workflow procedures. It provides a platform where you can build custom checklists, workflows, and digital procedures that enhance operational efficiency. With FAT FINGER, you can digitize your operations, reduce errors, and increase productivity.

Key Features of FAT FINGER

- Easy to Use: FAT FINGER’s user-friendly interface makes it easy for anyone to create and manage workflows.

- Customizable: You can tailor your workflows to meet your specific needs, ensuring maximum efficiency.

- Real-Time Analytics: FAT FINGER provides real-time data and analytics, allowing you to make informed decisions quickly.

- Integration: FAT FINGER seamlessly integrates with other systems, providing a holistic solution for your operations.

Developing Custom Control Room Monitoring Workflows with FAT FINGER

Control room monitoring is a critical aspect of many industries, including manufacturing, energy, and transportation. With FAT FINGER, you can develop custom workflows that enhance your control room monitoring procedures. Here’s how:

1. Digitizing Checklists and Procedures

With FAT FINGER, you can digitize your checklists and procedures, eliminating the need for paper-based systems. This not only reduces errors but also increases efficiency as data can be accessed and updated in real-time.

2. Customizing Workflows

FAT FINGER allows you to customize your workflows to suit your specific control room monitoring needs. You can create step-by-step procedures, assign tasks, set deadlines, and more. This ensures that your control room operations run smoothly and efficiently.

3. Leveraging Real-Time Analytics

Real-time analytics provided by FAT FINGER enable you to monitor your control room operations closely. You can track performance, identify bottlenecks, and make informed decisions to improve efficiency.

4. Integrating with Other Systems

FAT FINGER’s ability to integrate with other systems means you can have a comprehensive view of your control room operations. This integration facilitates better coordination and communication, leading to improved operational efficiency.

Case Study: Improving Control Room Efficiency with FAT FINGER

A leading energy company used FAT FINGER to improve its control room monitoring procedures. By digitizing their checklists and procedures, they were able to reduce errors and increase efficiency. The real-time analytics provided by FAT FINGER enabled them to monitor their operations closely and make informed decisions. As a result, they saw a significant improvement in their operational efficiency.

Conclusion

Developing custom control room monitoring workflows with FAT FINGER can significantly enhance your operational efficiency. Its user-friendly interface, customizable workflows, real-time analytics, and integration capabilities make it an ideal solution for control room monitoring. Whether you’re in manufacturing, energy, or transportation, FAT FINGER can help you unlock operational excellence in your control room.

Ready to revolutionize your control room operations? Build a digital workflow for free on FAT FINGER or schedule a demo today.