Corrosion management is a critical aspect of the energy industry, affecting everything from safety and efficiency to profitability. With the advent of digital solutions like FAT FINGER, a digital workflow procedure builder, companies can now effectively manage corrosion and ensure operational excellence. FAT FINGER empowers front-line teams to do their work correctly every time, unlocking operational excellence through checklists, workflows, and digital procedures.

Understanding Corrosion in the Energy Industry

Corrosion is a natural process that deteriorates materials, particularly metals, due to chemical reactions with their environment. In the energy industry, this can lead to equipment failure, safety hazards, and significant financial losses.

The Importance of Corrosion Management

Effective corrosion management is crucial in the energy industry for several reasons:

- It enhances safety by preventing equipment failure that could lead to accidents.

- It improves efficiency by ensuring that equipment operates at optimal levels.

- It boosts profitability by reducing the costs associated with equipment repair and replacement.

Challenges in Corrosion Management

Despite its importance, corrosion management in the energy industry faces several challenges:

- Lack of awareness and understanding of corrosion and its impacts.

- Insufficient resources dedicated to corrosion management.

- Difficulty in monitoring and detecting corrosion in hard-to-reach areas.

How FAT FINGER Can Help

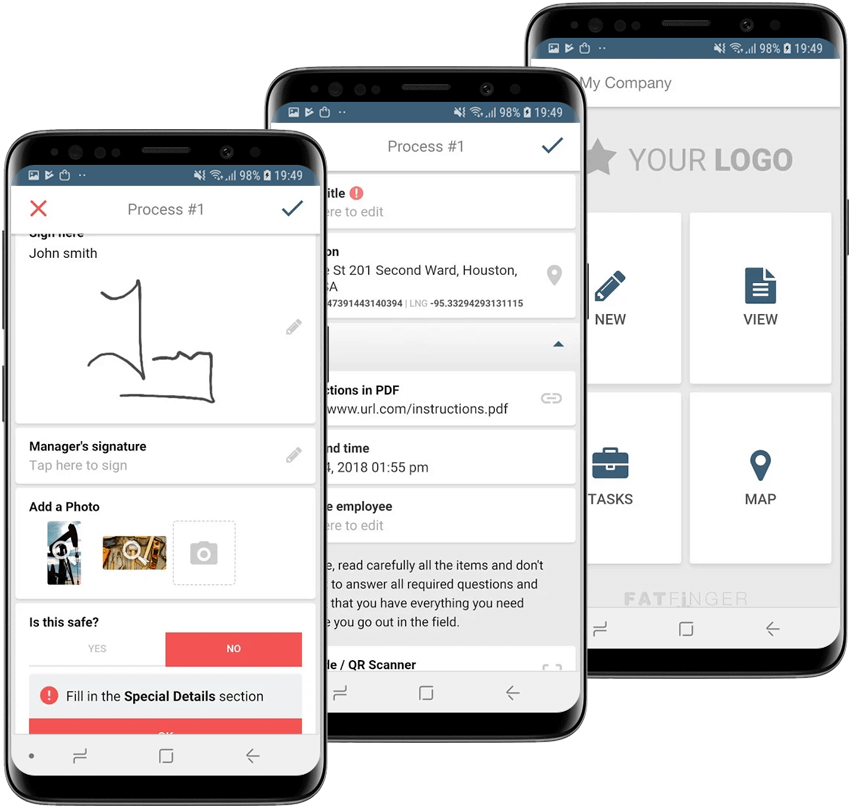

FAT FINGER offers a solution to these challenges through its digital workflow procedure builder. This tool allows companies to create checklists, workflows, and digital procedures for various safety, maintenance, and operations areas, including corrosion management.

Key Features of FAT FINGER

- Drag & Drop Workflow Builder: Easily create and customize workflows to suit your needs.

- Mobile & Desktop Workflows: Access your workflows from any device, anywhere, anytime.

- Dashboards: Monitor your operations in real-time with visual dashboards.

- Integrations: Connect FAT FINGER with your existing systems for seamless operations.

- Augmented Reality: Visualize your operations in a whole new way.

- Connect IoT Devices: Leverage the power of IoT for enhanced monitoring and detection.

- Artificial Intelligence Coaching: Get insights and recommendations to improve your operations.

Case Study: Corrosion Management with FAT FINGER

One energy company was able to significantly improve its corrosion management by using FAT FINGER. The company was struggling with frequent equipment failures due to corrosion. After implementing FAT FINGER, the company was able to create a comprehensive corrosion management workflow that included regular inspections, timely maintenance, and effective preventive measures. As a result, the company saw a significant reduction in equipment failures, leading to improved safety, efficiency, and profitability.

Conclusion

Corrosion management is a critical aspect of the energy industry, and digital solutions like FAT FINGER can play a key role in addressing this challenge. By leveraging the power of digital workflows, companies can effectively manage corrosion, enhance safety, improve efficiency, and boost profitability. Whether you’re dealing with safety, maintenance, or operations, FAT FINGER has the tools and features to help you achieve operational excellence.

Ready to take your corrosion management to the next level? Sign up for FAT FINGER or request a demo today.