As industries evolve, the need for real-time Hazard identification and risk assessment has become paramount. This is where connected worker solutions come into play, providing a platform for real-time data collection, analysis, and action. One such solution is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding FAT FINGER

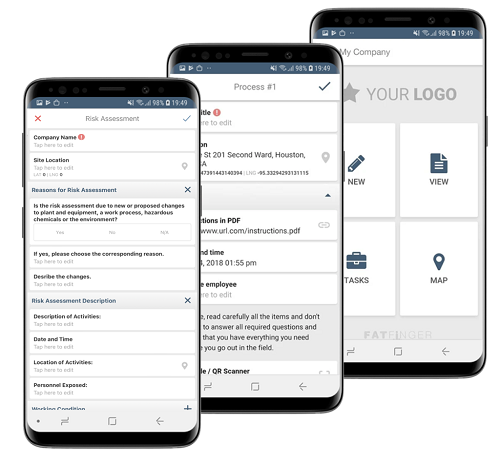

FAT FINGER is a comprehensive tool that allows you to build checklists, workflows, and digital procedures that unlock operational excellence. It features a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching.

With FAT FINGER, you can create digital workflows and checklists across safety, maintenance, and operations areas. These solutions include:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, risk assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

The Role of FAT FINGER in Real-Time Hazard Identification and Risk Assessment

FAT FINGER plays a crucial role in real-time Hazard identification and risk assessment. It provides a platform for workers to report hazards as they occur, allowing for immediate action and prevention of potential incidents. This real-time reporting can significantly reduce the risk of accidents and improve overall workplace safety.

Case Study: Improving Safety with FAT FINGER

Consider a manufacturing company that implemented FAT FINGER’s digital workflows for their safety procedures. The company was able to reduce the number of workplace accidents by 30% within the first year of implementation. This was achieved by enabling real-time reporting of hazards, which allowed for immediate action and prevention of potential incidents.

Benefits of Using FAT FINGER for Hazard Identification and Risk Assessment

There are several benefits of using FAT FINGER for Hazard identification and risk assessment, including:

- real-time reporting: FAT FINGER allows for immediate reporting of hazards, enabling quick action and prevention of potential incidents.

- Improved safety: With real-time Hazard identification and risk assessment, the risk of accidents can be significantly reduced.

- Increased efficiency: FAT FINGER’s digital workflows streamline safety procedures, reducing the time and resources required for Hazard identification and risk assessment.

- Compliance: FAT FINGER helps ensure compliance with safety regulations, reducing the risk of penalties and fines.

Conclusion

In conclusion, connected worker solutions like FAT FINGER are revolutionizing the way industries approach Hazard identification and risk assessment. By enabling real-time reporting and analysis, these solutions can significantly improve workplace safety and efficiency. Whether you’re in the safety, operations, or maintenance sector, FAT FINGER has a solution tailored to your needs.

Ready to take your Hazard identification and risk assessment to the next level? Sign up for FAT FINGER or request a demo today to see how our solutions can benefit your business.