Oil and gas operations stand out as complex and inherently hazardous industries in energy production. These industries play a vital role in fueling the world’s economy, but they also carry substantial risks.

This article will delve into the essential practices and procedures that oil rig operators must follow to guarantee the safety of their rigs and the people who operate them.

Common Hazards in Oil and Gas Operations

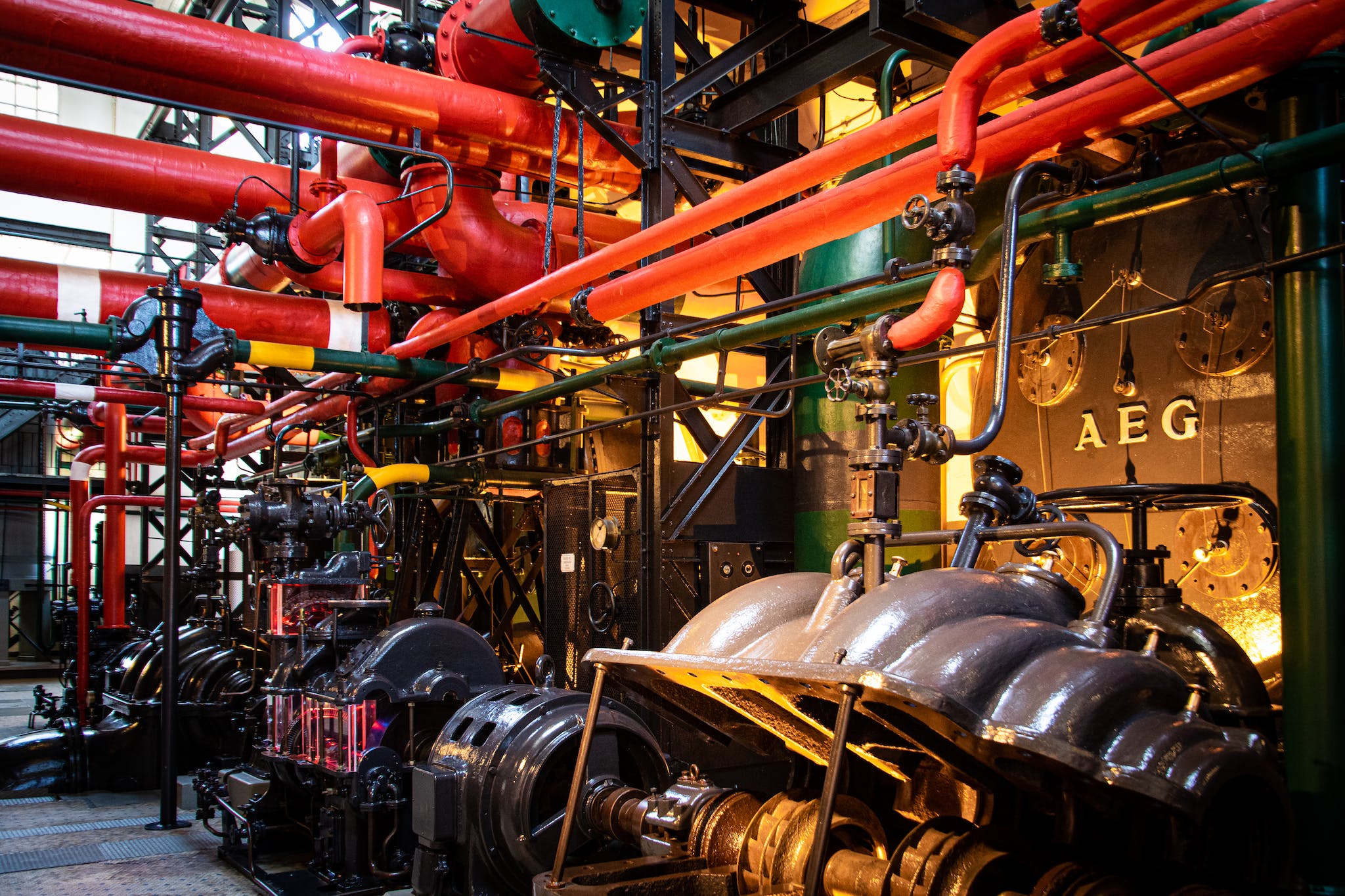

Explosions and Fires

Explosions and fires pose significant dangers in oil and gas operations, often with catastrophic consequences. These incidents can result from leaks, equipment malfunctions, or human errors. Mitigating these risks requires stringent safety protocols, fire-resistant materials, and well-trained emergency response teams.

Chemical Exposure

Oil and gas operations involve handling a variety of chemicals, some of which can be toxic or flammable. Workers may be exposed to these substances, leading to health issues. Proper training, personal protective equipment, and well-ventilated workspaces are key to reducing chemical exposure risks.

Equipment Failures

The failure of machinery and equipment can lead to accidents and production disruptions. Regular maintenance, thorough inspections, and quality control procedures are essential to minimize the risks associated with equipment failures.

Mitigation Strategies for Oil and Gas Hazards

Safety Training

Comprehensive safety training for all employees is crucial to hazard prevention. Workers must be aware of potential risks and how to respond to emergencies. Regular drills and safety meetings can enhance preparedness.

Hazard Identification

Effective hazard identification is the first step in mitigation. Encouraging employees to report potential risks and conducting thorough safety assessments can help identify and address hazards promptly.

Safety Equipment

Providing the right safety equipment, such as helmets, gloves, and respirators, is vital. It’s essential to ensure that equipment is in good condition and that workers know how to use it properly. Regular equipment inspections should be conducted to identify any issues.

Emergency Response Plans

Having well-developed emergency response plans in place is critical in the event of an incident. These plans should include procedures for evacuations, medical emergencies, and fire or explosion incidents. It’s essential to regularly review and update these plans to ensure their effectiveness.

Real-world Examples of Hazards in Oil and Gas Operation

Examining real incidents can illustrate the potential risks in oil and gas operations. Learning from past mistakes is essential to prevent future accidents.

Case Study 1: Uncontrolled Fire

In a certain oil and gas operation, a spark from a malfunctioning piece of machinery ignited a fire in a facility where flammable chemicals were stored. The fire quickly spread, causing significant damage to the infrastructure and production loss. This incident underscores the importance of regular equipment maintenance and inspections to identify potential faults. Furthermore, it highlights the need for fire-resistant storage units for flammable materials and efficient fire detection and suppression systems.

Case Study 2: Chemical Exposure

In another instance, an oil and gas worker suffered serious health issues due to prolonged exposure to hazardous chemicals. The worker was not provided with adequate personal protective equipment (PPE), and the workspace lacked proper ventilation. This incident could have been prevented if the company had enforced stricter safety measures, including the provision of appropriate PPE, regular health checks for its workers, and ensuring that workspaces are well-ventilated.

Case Study 3: Fall from an Elevated Structure

A worker in an oil rig fell from a height due to the absence of guardrails around an elevated platform. The worker was severely injured in the incident. The accident could have been avoided by implementing proper fall protection measures, such as the installation of guardrails around elevated worksites and the use of safety harnesses. Also, regular safety training to increase worker awareness about the risks of working at heights is crucial.

1. Preventive Maintenance

Preventive maintenance involves regular checks and repairs to prevent equipment breakdowns. This includes lubrication, cleaning, and calibration of machinery.

2. Corrective Maintenance

When issues are identified during inspections, corrective maintenance is required. This may involve replacing faulty components or conducting more extensive repairs.

3. Environmental Considerations

Oil rig operations can have a significant impact on the environment. Therefore, safety measures should include environmental protection, such as spill response plans and waste management procedures.

4. Regulatory Compliance

Oil rigs must comply with many regulations to ensure safety. Compliance involves adhering to local, national, and international standards, and the consequences for non-compliance can be severe.

Role of FAT FINGER in Oil and Gas Safety

FAT FINGER that helps operators streamline their inspection processes and identify potential issues before they become major problems. By helping to identify hazards and equipment malfunctions, FAT FINGER can greatly improve safety on oil rigs.

FAT FINGER features include:

- Automated inspections and data collection

- Real-time alerts for potential hazards or equipment malfunctions

- Detailed reporting and analysis for proactive maintenance planning

By utilizing technology like FAT FINGER, oil and gas industries can improve safety, reduce downtime, and ultimately increase productivity.

To learn more about how FAT FINGER can enhance the safety and productivity of your oil and gas operations, visit our website or schedule a demo today.

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io