In today’s fast-paced business environment, organizations must constantly evolve and adapt to stay competitive. One way to achieve this is by fostering a culture of continuous improvement. This involves regularly reviewing and refining processes to increase efficiency, improve quality, and drive innovation. A key tool that can facilitate this is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding Continuous Improvement

Continuous improvement is a management philosophy that encourages a proactive approach to improving processes, products, or services. It involves a commitment to constantly seeking ways to improve operations and create value for customers. This can be achieved through various methods, including Lean, Six Sigma, and Total Quality Management.

The Role of FAT FINGER in Continuous Improvement

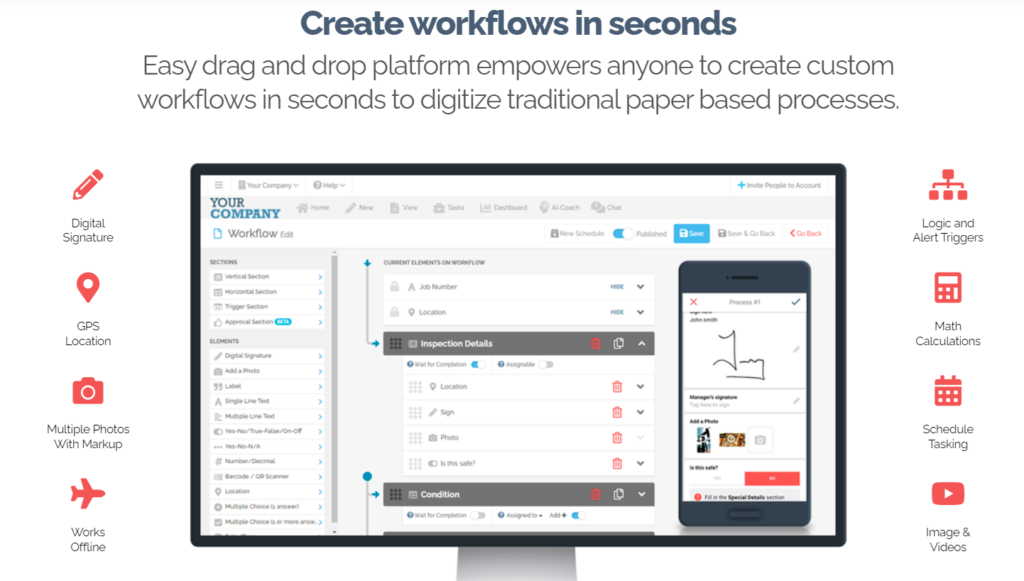

FAT FINGER plays a crucial role in fostering a culture of continuous improvement. Its features, such as the Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, enable organizations to streamline their processes, reduce errors, and increase efficiency.

For instance, the Drag & Drop Workflow Builder allows teams to easily create and modify workflows, enabling them to quickly adapt to changes and improve processes. The Mobile & Desktop Workflows feature ensures that teams can access and complete tasks from anywhere, increasing productivity and efficiency. Additionally, the Artificial Intelligence Coaching feature provides real-time guidance to teams, helping them to improve their performance and reduce errors.

Case Study: How FAT FINGER Facilitates Continuous Improvement

Consider the case of a manufacturing company that implemented FAT FINGER to improve its production processes. The company used the Drag & Drop Workflow Builder to create a workflow for its production process. This workflow was then deployed to the production team via the Mobile & Desktop Workflows feature.

With the help of the Artificial Intelligence Coaching feature, the team was able to identify areas of inefficiency in the process and make necessary improvements. As a result, the company saw a significant reduction in production errors and an increase in productivity.

Benefits of Building a Culture of Continuous Improvement

- Increased efficiency and productivity

- Improved quality of products or services

- Enhanced customer satisfaction

- Increased employee engagement and morale

- Improved competitiveness

Conclusion

Building a culture of continuous improvement is crucial for organizations to stay competitive in today’s business environment. Tools like FAT FINGER can play a significant role in facilitating this culture by enabling teams to streamline their processes, reduce errors, and increase efficiency. By fostering a culture of continuous improvement, organizations can enhance their competitiveness, improve their products or services, and create value for their customers.

Ready to start your journey towards continuous improvement? Sign up for FAT FINGER or request a demo today!