In the dynamic world of manufacturing, agility and composability are not just buzzwords but essential components for success. A Manufacturing Execution System (MES) that embodies these traits can revolutionize how a factory operates. Enter FAT FINGER, a digital workflow procedure builder that empowers front-line teams to excel. It’s a tool that ensures operational excellence through its robust features, including a drag-and-drop workflow builder, mobile and desktop workflows, dashboards, and more. Let’s delve into how a composable, agile MES, like FAT FINGER, can be the cornerstone of modern manufacturing.

The Building Blocks of a Composable MES Architecture

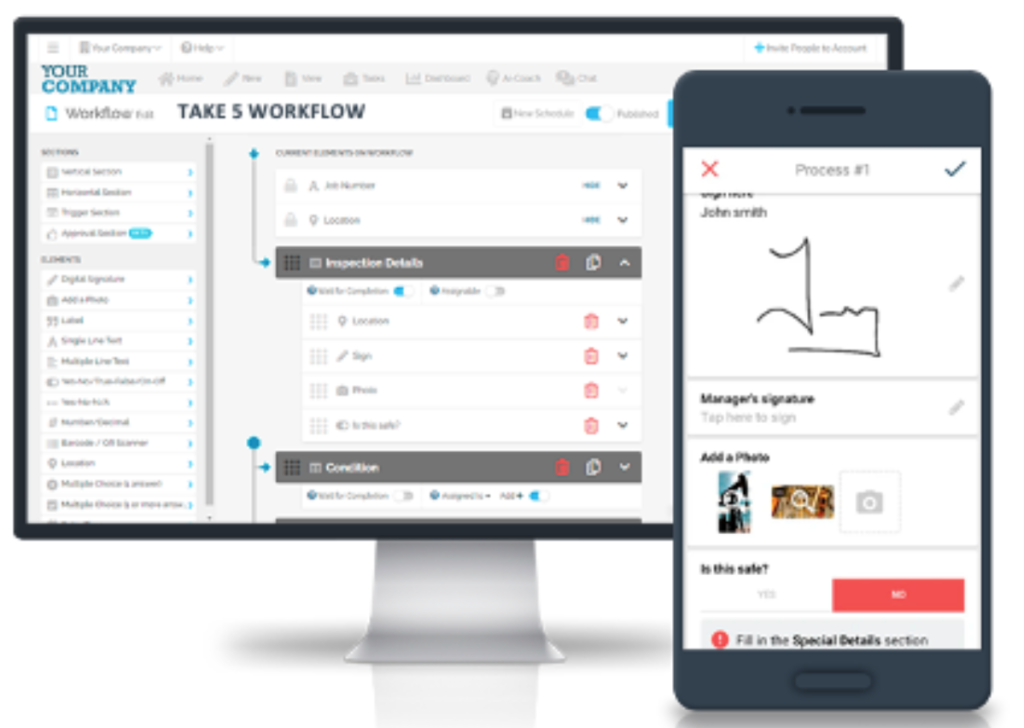

A composable MES architecture is modular. It allows manufacturers to tailor and scale their systems as needed. The key building blocks include modular software components, scalable cloud services, and robust APIs for integration. FAT FINGER seamlessly fits into this architecture with its drag-and-drop workflow builder. It allows for rapid development and deployment of custom procedures.

Moreover, the mobile and desktop workflows ensure that the system is accessible anywhere, at any time. This flexibility is crucial for real-time data collection and decision-making. FAT FINGER’s dashboards provide actionable insights, making it easier to monitor and optimize manufacturing processes.

Strategies for Achieving Agility in MES Deployment and Operations

Agility in MES deployment hinges on the ability to adapt quickly to changing demands. One strategy is to implement iterative development, where systems evolve through continuous improvement. FAT FINGER’s platform supports this approach with its intuitive design that allows for quick updates and changes without extensive downtime or retraining.

Another strategy is to leverage cloud-based solutions for scalability and flexibility. FAT FINGER’s cloud services ensure that your MES can grow with your business, without the need for significant upfront investment in infrastructure. Additionally, the use of artificial intelligence coaching can guide users through complex processes, ensuring that even the most intricate tasks are performed correctly.

Integrating MES with Other Enterprise Systems for Enhanced Composability

Integration is key to unlocking the full potential of a composable MES. By connecting MES with other enterprise systems, such as ERP, SCM, and CRM, businesses can achieve a seamless flow of information across the organization. FAT FINGER’s robust APIs facilitate these integrations, allowing data to move freely and securely.

This connectivity ensures that all parts of the business are informed and can react in unison to changes in production. For instance, integrating FAT FINGER with IoT devices can automate data collection, further enhancing the MES’s responsiveness and accuracy.

Future Trends: The Evolution of MES in the Age of Industry 4.0

As we move deeper into the age of Industry 4.0, MES systems are evolving. They are becoming more intelligent, predictive, and autonomous. The integration of augmented reality, for example, is transforming how workers interact with machinery and processes. FAT FINGER is at the forefront of this evolution with its augmented reality feature, which can guide workers through complex tasks in a highly visual and interactive manner.

Furthermore, the use of artificial intelligence and machine learning within MES is expected to grow. These technologies can predict maintenance needs, optimize production schedules, and enhance quality control. FAT FINGER’s AI coaching feature is a step towards this future, offering real-time guidance and support to front-line teams.

Conclusion

In conclusion, building a composable, agile MES is essential for manufacturers aiming to stay competitive in a rapidly changing industry. FAT FINGER provides the tools and features necessary to create such a system, empowering teams to perform their work correctly every time. With its user-friendly interface, integration capabilities, and cutting-edge features, FAT FINGER is an ideal partner in your journey towards operational excellence.

Are you ready to transform your manufacturing operations? Sign up for FAT FINGER or request a demo today to see how you can build a composable, agile MES that takes your production to the next level. Join the ranks of manufacturers who are embracing the future with FAT FINGER.