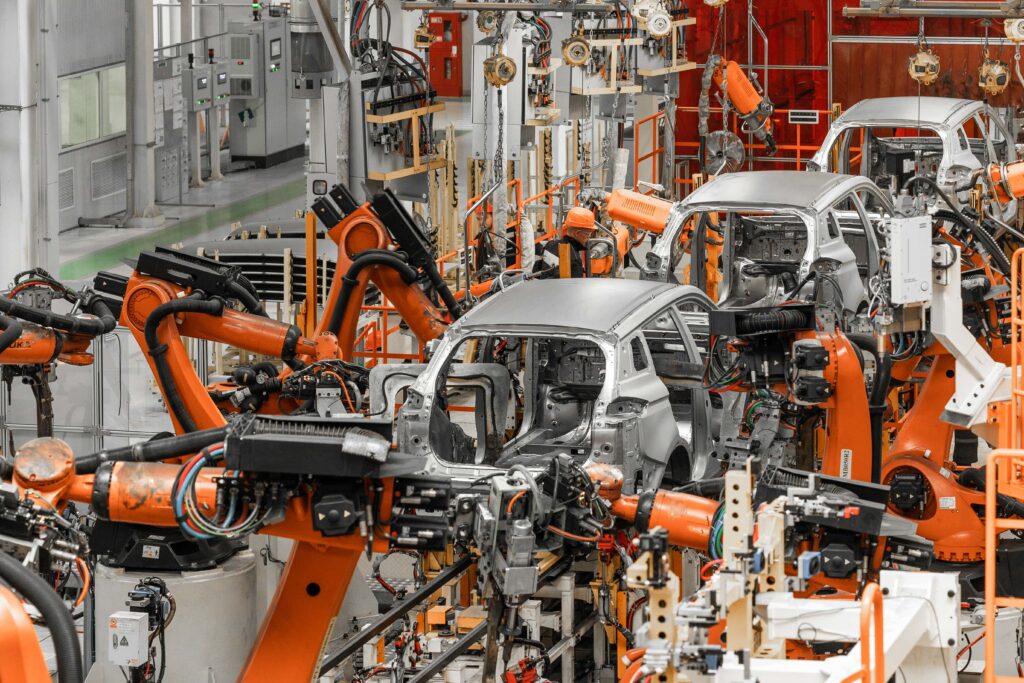

As the automotive industry continues to evolve, manufacturers are constantly seeking ways to improve efficiency and productivity. One area that has seen significant advancements is the process of vehicle manufacturing changeovers. This is where automation, and more specifically, software like FAT FINGER, comes into play.

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With FAT FINGER, you can build digital line clearance procedures to facilitate seamless line changeovers. But what exactly does this mean, and how does it benefit the automotive industry? Let’s delve deeper.

Understanding Line Changeovers in Vehicle Manufacturing

Line Changeover, also known as line clearance, is the process of verifying that all line changeover activities have been completed and that the line is ready to resume production. This process is crucial in vehicle manufacturing as it ensures that the production line is set up correctly for the next batch of vehicles to be produced.

The Impact of Automation on Line Changeovers

Automation has revolutionized the way line changeovers are conducted in vehicle manufacturing. Here’s how:

- Reduced Downtime: Automation significantly reduces the time taken to perform line changeovers, thereby minimizing production downtime.

- Improved Line Efficiency: Automated line clearance procedures ensure that all necessary steps are followed accurately and consistently, leading to improved line efficiency.

- Increased Product Quality: By eliminating human error, automation ensures that the quality of the vehicles produced is consistently high.

The Role of FAT FINGER in Automating Line Changeovers

FAT FINGER plays a pivotal role in automating line changeovers in vehicle manufacturing. Its features such as Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching make the process seamless and efficient.

Production Managers who have used FAT FINGER have praised its impact on their production line clearance process. One such testimonial states, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.”

Conclusion

In conclusion, automation plays a crucial role in enhancing vehicle manufacturing changeovers. It not only reduces downtime but also improves line efficiency and product quality. Software like FAT FINGER, with its advanced features, is leading the way in automating line changeovers, making it an indispensable tool in the automotive industry.

Experience the power of FAT FINGER for yourself. Request a demo today and see how it can revolutionize your vehicle manufacturing process. And if you’re convinced of its benefits, sign up to FAT FINGER and start your journey towards operational excellence.

Discover how automation can revolutionize your vehicle manufacturing changeovers. Learn more about the role of automation in enhancing efficiency, reducing downtime, and increasing productivity. Don’t wait, embrace the future of manufacturing today. Visit here to get started.