As the world continues to embrace the digital revolution, industries are increasingly turning to automation to streamline operations and improve efficiency. One area where automation is making a significant impact is in quality assurance within factories. This article explores how automation, particularly through the use of innovative software like FAT FINGER, is revolutionizing quality assurance in factories.

Are you interested in seeing how FAT FINGER can transform your factory operations? Request a demo today!

Understanding the Role of Automation in Quality Assurance

Automation in quality assurance involves the use of technology to perform tasks that were traditionally done manually. This includes tasks such as inspecting materials, monitoring production processes, and conducting Quality Control checks. Automation not only speeds up these processes but also reduces the risk of human error, leading to improved product quality and consistency.

The Power of FAT FINGER in Quality Assurance

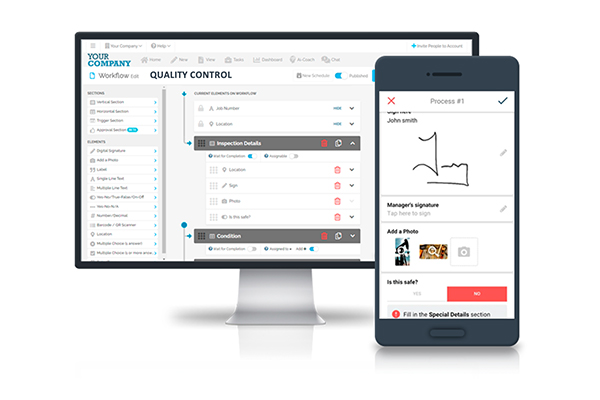

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With FAT FINGER, you can create powerful checklists to boost operational efficiency in your factory. Here are some examples:

- Material Inspection: With FAT FINGER, you can ensure the highest quality standards of your products with a digital material inspection. Defects can be identified early in the production process before they become too costly.

- Quality Control: FAT FINGER enables you to reach maximum production potential with customized automated workflows. With one click of a button, generate custom reports that will keep everyone on track for operational excellence.

- Shift Handover: Modernize your shift transition and watch the savings skyrocket. Automate tedious tasks quickly and keep your entire team in the loop.

- Facility Inspection: Streamline your checklists, SOPs, and inspections with FAT FINGER’s intuitive workflow solution. Revolutionize facility inspections quickly without compromising excellence.

- Line Changeover: Take your line changeover into a cost-effective future with digitalization. Get your team synced up in no time with automated recurring scheduling.

- Electronic Field Ticket: Upgrade your ticketing system and save big. Cut out tedious tasks and boost your team’s productivity with automated field reporting, workforce scheduling, and invoicing.

The Impact of Automation on Quality Assurance: A Closer Look

Automation, particularly through the use of software like FAT FINGER, has several key impacts on quality assurance in factories:

- Improved Accuracy: Automation reduces the risk of human error, leading to more accurate and consistent results.

- Increased Efficiency: Automated processes are typically faster and more efficient than manual ones, leading to increased productivity.

- Enhanced Compliance: Automation can help ensure that all processes are carried out in accordance with industry standards and regulations, enhancing compliance.

- Reduced Costs: By reducing the need for manual labor and minimizing errors, automation can lead to significant cost savings.

Conclusion

In conclusion, automation is revolutionizing quality assurance in factories, leading to improved accuracy, increased efficiency, enhanced compliance, and reduced costs. Software like FAT FINGER is at the forefront of this revolution, empowering front-line teams to do their work correctly every time and unlocking operational excellence.

Are you ready to experience the power of FAT FINGER in your factory? Build a safety checklist with FAT FINGER today and take the first step towards a more efficient, accurate, and cost-effective quality assurance process.

Discover how automation can revolutionize your factory’s quality assurance process. Learn more about the impact and benefits of integrating automated systems into your operations. Don’t miss out on this opportunity to enhance efficiency and accuracy in your factory. Request A Demo today.