Non-Destructive Testing (NDT) is a crucial aspect of many industries, including manufacturing, construction, and aerospace. It involves inspecting, testing, or evaluating materials, components, or assemblies for discontinuities or differences in characteristics without destroying the serviceability of the part or system. With the advent of technology, NDT techniques have significantly advanced, leading to more efficient and accurate inspections. This article explores these advancements and how software like FAT FINGER can enhance the process.

What is FAT FINGER?

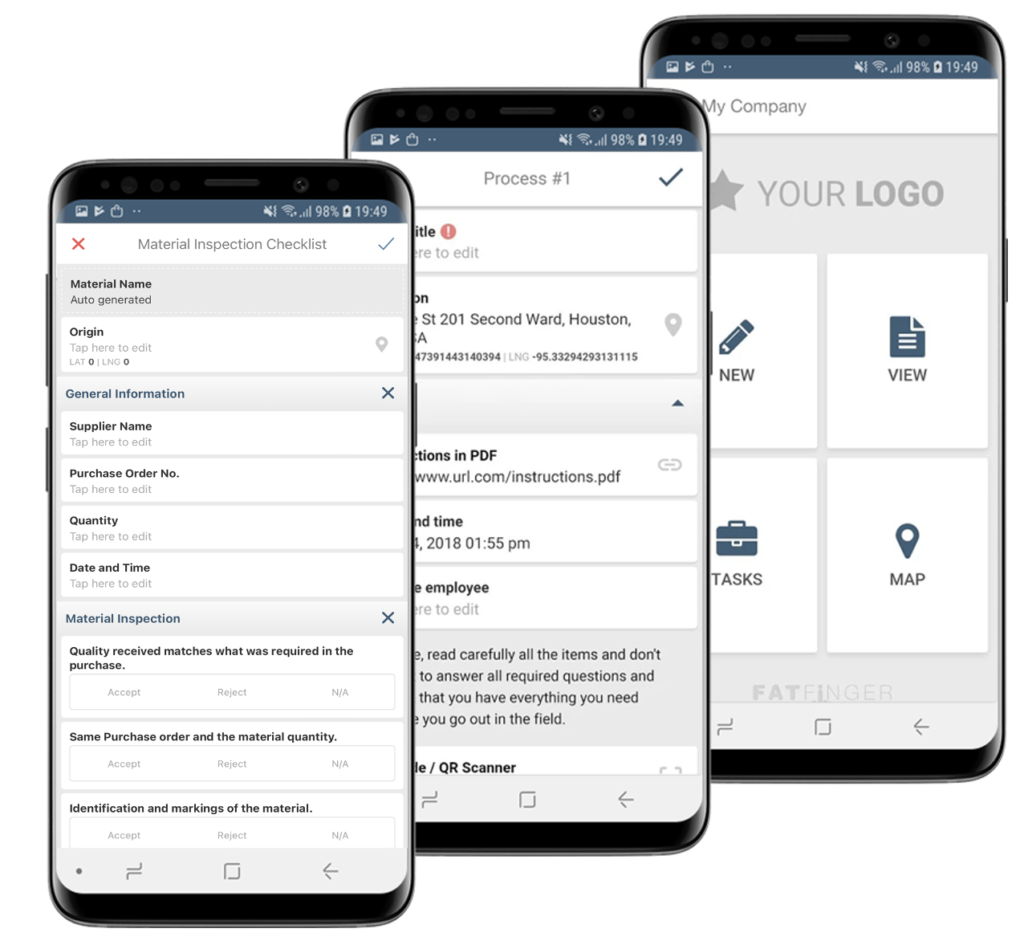

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is revolutionizing the way industries operate. One of the areas where FAT FINGER can be utilized is material inspection, a critical component of operations.

Advancements in NDT Techniques

Over the years, NDT techniques have evolved to become more efficient, accurate, and safer. Here are some of the significant advancements:

- Phased Array Ultrasonic Testing (PAUT): This advanced method of ultrasonic testing has applications in several industrial sectors. PAUT allows for the electronic manipulation of the ultrasonic beams, which can be steered, scanned, swept, and focused electronically.

- Time of Flight Diffraction (TOFD): TOFD is a reliable and accurate method for the detection and sizing of defects in welds. It uses the time of flight of an ultrasonic pulse to find and size defects.

- Guided Wave Ultrasonic Testing (GWUT): This method uses low-frequency ultrasonic waves that can travel a long distance with little loss in energy. GWUT is particularly useful for inspecting long structures like pipelines and rails.

- Computed/Digital Radiography: This technique uses a digital detector instead of traditional film to record and manipulate the image. It offers several advantages over traditional radiography, including improved imaging capabilities, reduced exposure times, and environmental benefits.

Role of FAT FINGER in Material Inspection

FAT FINGER can play a significant role in material inspection by streamlining the process and ensuring accuracy. Here’s how:

- Checklists and Workflows: FAT FINGER allows you to create digital checklists and workflows for material inspection. This ensures that the inspection process is standardized and followed correctly every time.

- Integration: FAT FINGER can be integrated with other systems, allowing for seamless data transfer and reducing the chances of errors.

- Artificial Intelligence Coaching: With AI coaching, FAT FINGER can guide inspectors through the process, ensuring that no steps are missed and that the inspection is carried out correctly.

- Augmented Reality: FAT FINGER’s augmented reality feature can be used to enhance the inspection process by overlaying digital information onto the physical world.

Conclusion

Advancements in NDT techniques have revolutionized the way industries carry out material inspection. These techniques, coupled with software like FAT FINGER, can significantly enhance the inspection process, ensuring accuracy, efficiency, and safety. Whether it’s creating digital workflows, integrating with other systems, or using AI and augmented reality, FAT FINGER is paving the way for operational excellence in material inspection.

Ready to take your material inspection process to the next level?

Discover the latest advancements in Non-Destructive Testing (NDT) Techniques for Material Inspection. Stay ahead of the curve and ensure the integrity of your materials without causing any damage. Learn more and explore the possibilities today.