Operational excellence is a critical factor in the success of any business. It involves streamlining processes, reducing waste, and improving productivity. One of the most effective ways to achieve this is through the use of digital workflow procedure builders like FAT FINGER. This innovative software empowers front-line teams to perform their work correctly every time, unlocking operational excellence across various safety, maintenance, and operations areas.

Understanding FAT FINGER

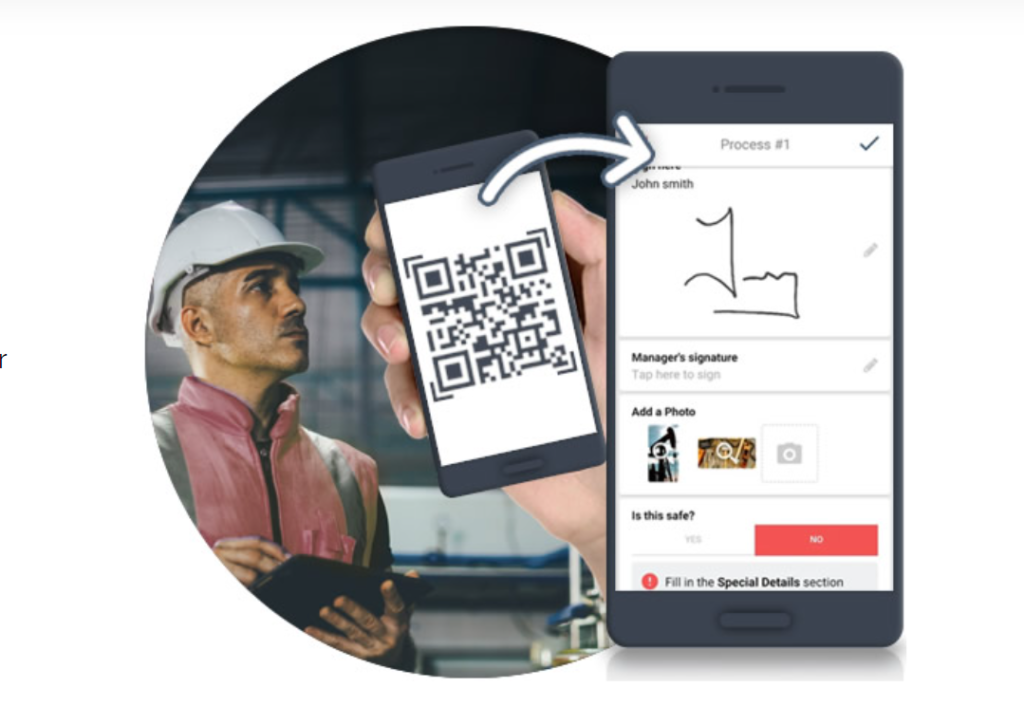

FAT FINGER is a digital workflow procedure builder that allows businesses to create checklists, workflows, and digital procedures. It features a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching. These features enable businesses to streamline their operations and achieve operational excellence.

How FAT FINGER Enhances Operational Excellence

FAT FINGER’s connected worker solutions offer numerous benefits that contribute to operational excellence. Here are some of the key ways:

- Improved Efficiency: FAT FINGER’s drag & drop workflow builder allows businesses to create custom workflows that streamline operations and reduce waste.

- Increased Productivity: With mobile & desktop workflows, employees can access and complete tasks from anywhere, leading to increased productivity.

- Enhanced Decision-Making: The software’s dashboards provide real-time data and insights, enabling businesses to make informed decisions.

- Seamless Integration: FAT FINGER integrates with other business systems, ensuring seamless data flow and improved operational efficiency.

- Advanced Technology: The software’s augmented reality, IoT device connectivity, and artificial intelligence coaching features offer advanced solutions for operational challenges.

FAT FINGER in Action: Case Studies

Many businesses have already experienced the benefits of FAT FINGER’s connected worker solutions. Here are a few examples:

- A manufacturing company used FAT FINGER to create custom workflows for their production rounds and line changeovers. This resulted in a 30% increase in productivity and a significant reduction in waste.

- A logistics company implemented FAT FINGER’s mobile & desktop workflows for their truck inspection checks and field tickets. This led to a 50% reduction in paperwork and a 20% increase in operational efficiency.

- An energy company utilized FAT FINGER’s dashboards and integrations for their preventive maintenance inspections and predictive maintenance. This enabled them to make data-driven decisions, leading to a 40% decrease in equipment downtime.

Conclusion

Achieving operational excellence is no small feat, but with the right tools and strategies, it is possible. FAT FINGER’s connected worker solutions offer a comprehensive approach to streamlining operations, reducing waste, and improving productivity. With its advanced features and proven results, FAT FINGER is a valuable asset for any business striving for operational excellence.

Ready to unlock operational excellence in your business? Achieve operational excellence with FAT FINGER’s Connected Worker Solutions. Streamline your processes, increase productivity, and enhance your business performance. Don’t wait, start your journey towards operational excellence now.