The Oil and Gas Industry and the Manufacturing sector are among the most hazardous industries, with increased risks of accidents and fatalities. These industries are particularly vulnerable to near misses that can result in severe injuries and safety errors.

In this article, we will explore near miss reporting, and its importance in the Oil and Gas Industry and the Manufacturing sector, and provide some examples of how near-miss reporting has helped companies prevent future accidents.

The Oil and Gas Industry is highly dependent on safety and requires constant attention to prevent major safety incidents. Near-miss reporting plays a significant role in identifying potential hazards and preventing future accidents. For instance, a near-miss event in the Oil and Gas industry could be a gas leak, equipment failure, or a pipeline puncture that could have resulted in a significant disaster. By identifying the root cause of a near miss and providing recommendations for improvement, companies can enhance safety protocols and improve their overall safety performance.

Near Miss Reporting in Manufacturing Sector

In the manufacturing sector, where large equipment and machinery are frequently in use, near misses are a common occurrence. Without proper reporting, an incident could escalate into a severe accident. For example, a near miss in the manufacturing sector could be when a machine malfunctions or equipment failure occurs. Near miss reporting can result in safer workplaces, reduced costs and improved productivity.

Examples of Near Miss Reporting

Several companies in the Oil and Gas industry and the manufacturing sector have implemented successful near-miss reporting programs. For example, in the oil and gas industry, ExxonMobil implemented a near-miss reporting system that allowed employees to report their observations of potentially hazardous situations. This program provided the company with valuable information on potential hazards, which helped to prevent severe accidents.

In the manufacturing sector, many American multinational corporations implemented a reporting system that resulted in the identification of many near-miss incidents.

Through this program, the company implemented corrective actions that reduced the potential for accidents and increased employee safety awareness.

Other near misses example:

–Faulty machinery can lead to dangerous accidents and injuries if not dealt with appropriately. A near miss can occur when an issue with equipment is identified before it results in harm, such as a motor overheating and starting a fire.

–Slip and fall incidents are common near misses in industrial settings. They may occur when floors and walkways are unclear or wet and slippery without proper signage.

–Chemical spills can pose a significant risk to workers if not handled appropriately. A near miss could occur when a container is poorly secured, storage is substandard, or transportation of hazardous materials is mishandled.

Recognizing near misses is critical in creating a safer work environment; it empowers workers to identify issues that could cause harm. The importance of this proactive approach cannot be overstated, where taking corrective measures promptly translates to a safer and more productive workplace.

About FAT FINGER

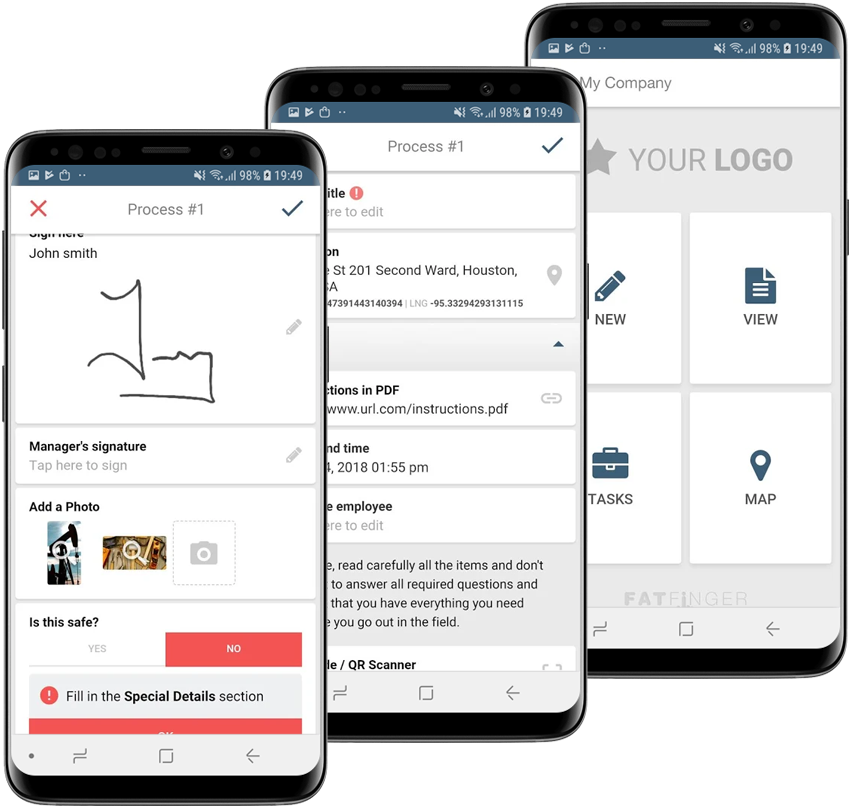

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io

Near-miss reporting for everyone – Anytime and anywhere.

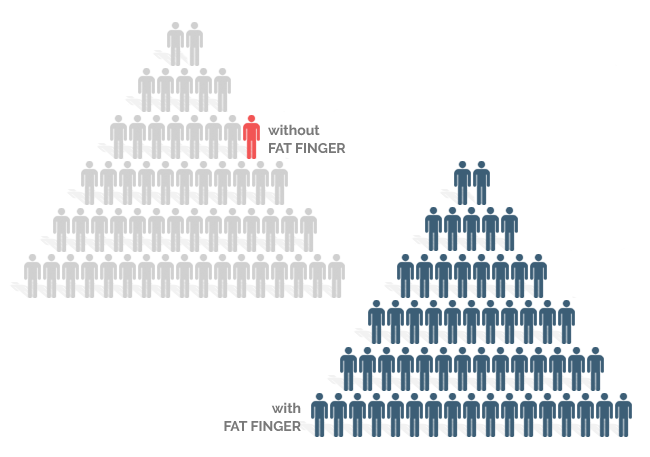

We empower EVERYONE to initiate and create positive change to improve the company’s safety records no matter where you are. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

Data powerhouse – Keeping everything in one place.

Data are stored in the cloud and available in real-time to everyone who needs it. All your up-to-date safety work instructions and training content are available across any device as employees perform the work.

Advanced Analytics- What gets measured, gets managed.

Every single piece of information captured by FAT FINGER users will feed your company analytics in real time. FAT FINGER provides you with valuable insights to help improve your workplace safety. With detailed dashboards, you can quickly identify areas of improvement and track your progress over time.