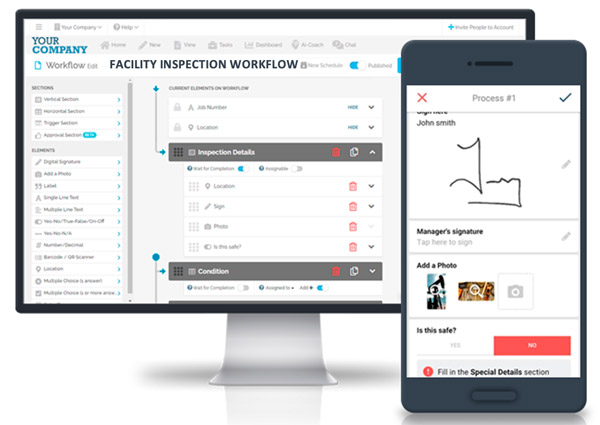

Ensuring the safety and functionality of oil and gas facilities is a critical task that requires meticulous attention to detail. One of the most effective ways to maintain these facilities is by conducting regular inspections using a comprehensive checklist. With the help of FAT FINGER, a digital workflow procedure builder, you can elevate your team’s facility inspection to new heights.

FAT FINGER empowers frontline teams to do their work correctly every time, by letting you build checklists, workflows, and digital procedures that unlock operational excellence. Schedule a demo today to see how FAT FINGER can revolutionize your facility inspections.

1. Safety Equipment Inspection

One of the first things to check during an oil and gas facility inspection is the safety equipment. This includes fire extinguishers, safety showers, eye wash stations, and personal protective equipment. FAT FINGER’s drag and drop workflow builder can help you create a comprehensive checklist for this task.

2. Hazardous Material Handling

Proper handling and storage of hazardous materials is crucial in an oil and gas facility. With FAT FINGER, you can build workflows that ensure all procedures are followed correctly, reducing the risk of accidents.

3. Equipment Maintenance

Regular maintenance of equipment is essential to prevent breakdowns and costly repairs. FAT FINGER’s mobile and desktop workflows can help you keep track of maintenance schedules and tasks.

4. Emergency Response Plan

Every facility should have an emergency response plan in place. FAT FINGER can help you create a digital procedure that outlines the steps to take in case of an emergency.

5. Training and Competency

Ensuring that all staff are properly trained and competent in their roles is a key aspect of facility safety. FAT FINGER’s artificial intelligence coaching can help you ensure that your team is up to date with the latest safety procedures.

6. Environmental Controls

Environmental controls such as waste management and emission controls should be regularly inspected. FAT FINGER’s dashboards can help you monitor these controls effectively.

7. Facility Cleanliness

A clean facility is a safe facility. With FAT FINGER, you can create checklists to ensure that cleanliness standards are maintained.

8. Compliance with Regulations

Compliance with local and international regulations is crucial in the oil and gas industry. FAT FINGER’s integrations can help you stay on top of these regulations and ensure compliance.

Conclusion

Conducting regular inspections using a comprehensive checklist is crucial for maintaining a safe and functional oil and gas facility. With FAT FINGER, you can streamline your checklists, SOPs, and inspections with an intuitive workflow solution. Enjoy the ease of dragging and dropping digital procedures onto a platform directly where work is done, and generate professional reports in an instant.

Revolutionize your facility inspections quickly without compromising excellence. Build your facility inspection workflow for free with FAT FINGER or schedule a demo today.

Don’t compromise on safety! Ensure your oil and gas facility meets all safety standards with our comprehensive 8 Point Inspection Checklist. To learn more about how our checklist can help you maintain a safe and efficient operation, Schedule a demo today.