In the manufacturing industry, plant turnaround and shift turnover are critical processes often used interchangeably. However, it is crucial to note that they are two distinct processes that require different approaches

In this post, we’ll delve into plant turnaround and shift turnover, highlight their differences, and provide insights into how to handle them more effectively.

Plant Turnaround Vs. Turnover

Plant turnaround, also known as plant shutdown, is an essential maintenance process that involves shutting down entire production lines or sections of the factory to carry out repairs, maintenance, and upgrades. The objective is to keep equipment in optimal condition, prevent breakdowns, and ensure safety. Typically, plant turnaround occurs every three to five years. During this period, a team of maintenance workers, engineers, and contractors tear down equipment, inspect them thoroughly, replace worn-out parts, and carry out the necessary upgrades. Turnaround periods can last weeks or months, depending on the scope of work.

On the other hand, shift turnover transfers responsibilities from one shift owner to the next. The primary objective is to ensure a seamless transition between periods and maintain continuity in operations. Shift turnover is critical in industries where operations run 24/7, such as manufacturing and oil and gas. During shift turnover, the outgoing team briefs the incoming team about ongoing tasks, issues, changes, and any other critical information needed for a smooth handover. Proper shift turnover procedures can reduce errors, improve communication, and foster teamwork.

One of the critical differences between turnaround and turnover is their frequency. While plant turnaround occurs every few years, shift turnover happens multiple times daily or weekly.

Turnaround is also a complex, large-scale operation that requires considerable planning, preparation, and resources. Turnaround can have a significant impact on the facility’s productivity and finances.On the other hand, shift turnover is a routine process that, if done correctly, will not affect the facility’s operations.

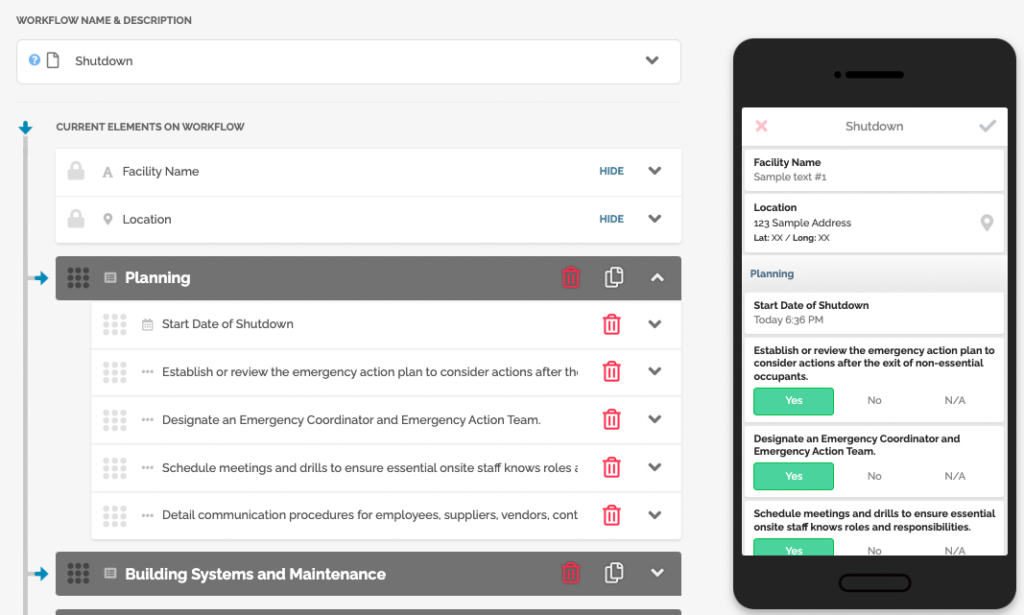

Manufacturers must establish effective communication channels, maintain clear procedures and protocols, and leverage technology to handle turnaround and turnover better. FAT FINGER provides easy-to-use workflows to help you manage your shutdown program.

With intuitive workflow, you can drag & drop digital procedures, control scheduling, and oversee maintenance. Get a comprehensive view of all your assets during the shutdown, history records, maintenance updates, SOPs, and more while inside the app.

Plant turnaround and shift turnover are two distinct processes that manufacturers need to understand, manage, and optimize. Manufacturers that establish efficient strategies for managing turnaround and turnover can minimize downtime, reduce costs and optimize asset management.

About FAT FINGER

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io