Asset inspections are a critical component of the oil and gas industry, ensuring the safety, efficiency, and longevity of equipment. With the advent of digital solutions like FAT FINGER, these different types of asset inspections have become more streamlined and effective.

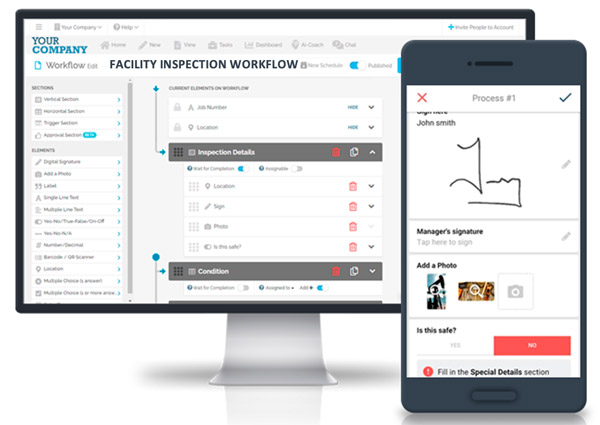

FAT FINGER is a digital workflow procedure builder that allows you to create mobile asset inspection workflows, making it easier to monitor assets and prevent unwanted breakdowns.

Request a demo to see how FAT FINGER can revolutionize your asset inspection process.

The Importance of Asset Inspections

Asset inspections are essential for maintaining the integrity of equipment and systems in the oil and gas industry. They help identify potential issues before they escalate into costly repairs or dangerous accidents. Regular inspections also ensure compliance with industry regulations and standards, protecting companies from legal repercussions and reputational damage.

Types of Asset Inspections in Oil and Gas

There are several types of asset inspections utilized in the oil and gas industry, each serving a specific purpose. Here are the most common ones:

- Visual Inspections: These are the most basic form of inspections, involving a visual check of equipment and systems to identify any obvious issues or anomalies.

- Non-Destructive Testing (NDT): NDT involves using methods like ultrasonic testing, magnetic particle inspection, and radiographic testing to inspect assets without causing any damage.

- Corrosion Under Insulation (CUI) Inspections: CUI inspections are crucial in the oil and gas industry, as they help detect corrosion under insulation, a common issue that can lead to equipment failure.

- Drone Inspections: Drones are increasingly being used for inspections, especially in hard-to-reach areas. They can capture high-resolution images and videos, providing detailed insights into the condition of assets.

Challenges in Asset Inspections

Despite their importance, asset inspections in the oil and gas industry often face several challenges. These include the vastness and complexity of assets, harsh operating conditions, and the need for timely and accurate data. Manual inspections can be time-consuming, error-prone, and potentially dangerous for inspectors.

Revolutionizing Asset Inspections with FAT FINGER

FAT FINGER is designed to address these challenges head-on. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER simplifies and enhances the asset inspection process.

With FAT FINGER, you can build mobile asset inspection workflows that allow for real-time data collection and analysis. This not only improves the accuracy of inspections but also enables faster decision-making. The software’s augmented reality feature further enhances inspections, allowing inspectors to visualize data in a more interactive and intuitive way.

Moreover, FAT FINGER’s AI coaching feature provides guidance during inspections, reducing the likelihood of errors and improving the overall quality of inspections. The software also integrates with other systems, allowing for seamless data sharing and collaboration.

Conclusion

Asset inspections are a vital part of the oil and gas industry, ensuring the safety and efficiency of operations. While these inspections can be challenging, digital solutions like FAT FINGER are revolutionizing the process, making inspections more accurate, efficient, and safe. With its robust features and capabilities, FAT FINGER is poised to become an indispensable tool in the oil and gas industry’s asset inspection process.

Ready to revolutionize your asset inspection process? Create a mobile asset inspection workflow for free on FAT FINGER today.