In the oil and gas industry, the term “turnaround” refers to a scheduled event where an entire process unit of an industrial plant is taken offline for maintenance, inspection, and upgrades. This process is crucial for ensuring the safety, efficiency, and longevity of the plant’s operations. Turnarounds are complex, costly, and time-consuming, but they are essential for preventing unplanned outages and catastrophic failures. In this article, we will delve into the intricacies of turnarounds, their importance, and how digital solutions like FAT FINGER can streamline the process. Request a demo to see how FAT FINGER can revolutionize your turnaround management.

The Importance of Turnarounds

Turnarounds are vital for several reasons. They ensure that equipment is functioning correctly, help in identifying potential issues before they become critical, and allow for necessary upgrades to be implemented. Here are some key reasons why turnarounds are indispensable:

- Safety: Regular maintenance and inspections during turnarounds help in identifying and mitigating potential hazards, ensuring the safety of the plant and its workers.

- Efficiency: Turnarounds allow for the optimization of equipment and processes, leading to improved operational efficiency and reduced downtime.

- Compliance: Regulatory bodies often require periodic inspections and maintenance to ensure that plants adhere to safety and environmental standards.

- Longevity: Regular maintenance extends the lifespan of equipment, reducing the need for costly replacements and unplanned outages.

Challenges in Turnaround Management

Managing a turnaround is a complex task that involves meticulous planning, coordination, and execution. Some of the common challenges faced during turnarounds include:

- Time Constraints: Turnarounds are time-sensitive, and any delays can lead to significant financial losses.

- Resource Allocation: Ensuring that the right resources, including skilled labor and equipment, are available when needed is crucial.

- Communication: Effective communication among various teams and stakeholders is essential for smooth execution.

- Data Management: Keeping track of vast amounts of data, including inspection reports, maintenance records, and schedules, can be overwhelming.

Case Study: Successful Turnaround Management

Let’s consider a case study of a major oil refinery that successfully managed a turnaround using digital workflows. The refinery faced several challenges, including tight deadlines, resource constraints, and the need for effective communication among multiple teams. By implementing a digital solution like FAT FINGER, the refinery was able to:

- Streamline Planning: The digital platform allowed for detailed planning and scheduling, ensuring that all tasks were completed on time.

- Optimize Resource Allocation: Real-time data and analytics helped in efficiently allocating resources, reducing downtime and costs.

- Enhance Communication: The platform facilitated seamless communication among teams, ensuring that everyone was on the same page.

- Improve Data Management: All data was stored in a centralized location, making it easy to access and analyze.

As a result, the refinery completed the turnaround ahead of schedule and within budget, demonstrating the effectiveness of digital solutions in managing complex projects.

How FAT FINGER Can Help

FAT FINGER is a digital workflow platform designed to simplify and streamline turnaround management in the oil and gas industry. Here are some ways FAT FINGER can help:

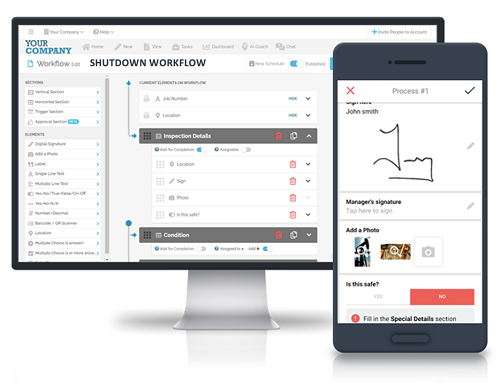

- Automated Workflows: FAT FINGER allows you to create automated workflows for planning, scheduling, and executing turnaround tasks, reducing the risk of human error.

- Real-Time Data: The platform provides real-time data and analytics, helping you make informed decisions and optimize resource allocation.

- Centralized Data Management: All data is stored in a centralized location, making it easy to access, analyze, and share with stakeholders.

- Enhanced Communication: FAT FINGER facilitates seamless communication among teams, ensuring that everyone is on the same page and reducing the risk of miscommunication.

- Compliance and Reporting: The platform helps you stay compliant with regulatory requirements by providing detailed reports and documentation.

Conclusion

Turnarounds are a critical aspect of maintaining the safety, efficiency, and longevity of oil and gas operations. While they present several challenges, digital solutions like FAT FINGER can significantly streamline the process, ensuring that turnarounds are completed on time and within budget. By leveraging automated workflows, real-time data, and enhanced communication, FAT FINGER helps you overcome the complexities of turnaround management. Create a shutdown and turnaround workflow for free on FAT FINGER or request a demo to see how our platform can revolutionize your turnaround management.