The shutdown process in the oil and gas industry is a critical operation that ensures the safety, efficiency, and longevity of equipment and facilities. This process involves the systematic cessation of operations, maintenance, and inspection activities to address potential issues and prevent catastrophic failures. Understanding the shutdown process is essential for industry professionals to maintain operational integrity and safety standards. Request a demo of FAT FINGER to see how digital workflows can streamline your shutdown process.

Stages in A Shutdown Procedure

The shutdown process in oil and gas is a planned event where production is halted to perform necessary maintenance, inspections, and repairs. This process is crucial for ensuring the safety and reliability of equipment and infrastructure. It involves several stages, including planning, execution, and post-shutdown activities.

Planning Phase

The planning phase is the most critical part of the shutdown process. It involves detailed preparation to ensure that all necessary tasks are identified and scheduled. Key activities in this phase include:

- Identifying the scope of work

- Developing a detailed schedule

- Allocating resources and personnel

- Ensuring compliance with safety and regulatory standards

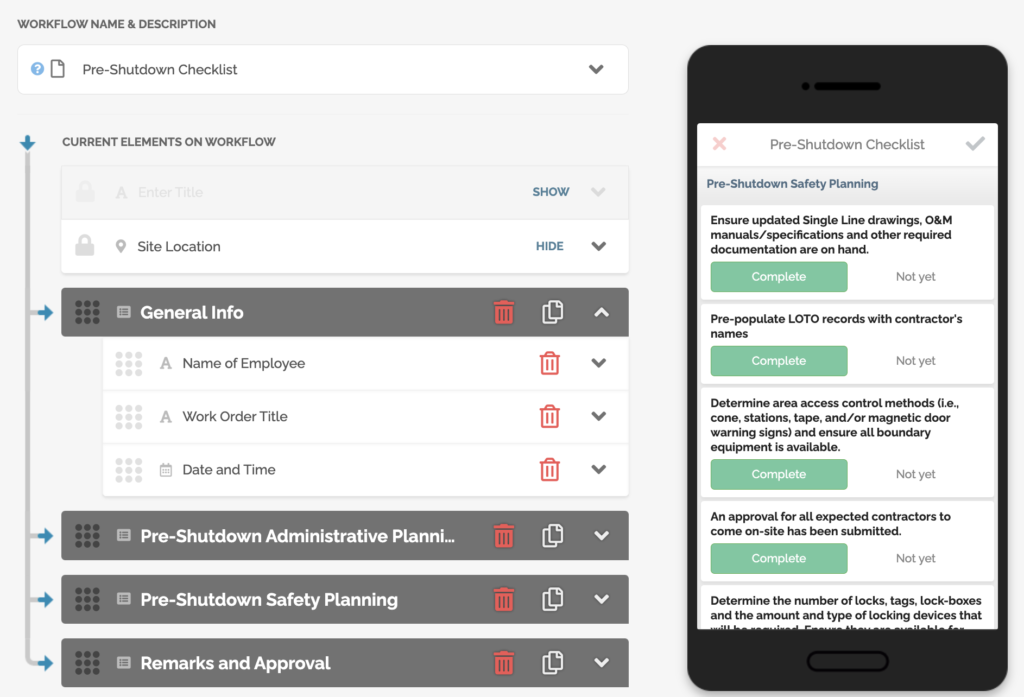

Effective planning minimizes downtime and ensures that all necessary tasks are completed efficiently. FAT FINGER’s digital workflows can help streamline the planning phase by providing a centralized platform for task management and resource allocation.

Execution Phase

The execution phase involves carrying out the planned activities. This phase requires meticulous coordination and communication to ensure that all tasks are completed safely and efficiently. Key activities in this phase include:

- Shutting down equipment and systems

- Performing maintenance and repairs

- Conducting inspections and tests

- Documenting all activities and findings

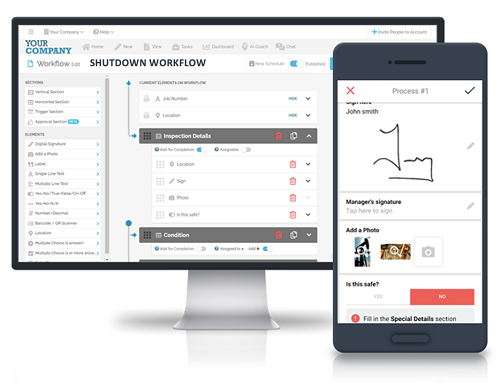

During the execution phase, it is essential to monitor progress and address any issues that arise promptly. FAT FINGER’s real-time monitoring and reporting features can help ensure that the execution phase runs smoothly and efficiently.

Post-Shutdown Activities

After the shutdown activities are completed, the post-shutdown phase involves restarting equipment and systems and ensuring that everything is functioning correctly. Key activities in this phase include:

- Restarting equipment and systems

- Conducting final inspections and tests

- Documenting the shutdown process and outcomes

- Reviewing and analyzing the shutdown process for future improvements

Effective post-shutdown activities ensure that the facility returns to normal operations safely and efficiently. FAT FINGER’s digital workflows can help streamline post-shutdown activities by providing a centralized platform for documentation and analysis.

Challenges in the Shutdown Process

The shutdown process in oil and gas is complex and challenging. Several factors can impact the success of a shutdown, including:

- Coordination and communication

- Resource allocation and management

- Compliance with safety and regulatory standards

- Unforeseen issues and delays

These challenges can lead to increased downtime, higher costs, and potential safety risks. FAT FINGER’s digital workflows can help address these challenges by providing a centralized platform for task management, resource allocation, and real-time monitoring.

Case Studies: Successful Shutdowns

Several case studies highlight the importance of effective shutdown processes in the oil and gas industry. For example, a major oil refinery in the United States successfully completed a shutdown by implementing a detailed planning and execution strategy. Key factors that contributed to their success included:

- Comprehensive planning and scheduling

- Effective communication and coordination

- Real-time monitoring and reporting

- Compliance with safety and regulatory standards

By leveraging FAT FINGER’s digital workflows, the refinery was able to streamline their shutdown process, minimize downtime, and ensure the safety and reliability of their equipment and infrastructure.

The Role of Digital Workflows in the Shutdown Process

Digital workflows play a crucial role in streamlining the shutdown process in oil and gas. By providing a centralized platform for task management, resource allocation, and real-time monitoring, digital workflows can help address the challenges associated with shutdowns. Key benefits of digital workflows include:

- Improved coordination and communication

- Efficient resource allocation and management

- Real-time monitoring and reporting

- Enhanced compliance with safety and regulatory standards

FAT FINGER’s digital workflows are designed to streamline the shutdown process by providing a user-friendly platform for managing tasks, resources, and real-time data. By leveraging FAT FINGER’s digital workflows, oil and gas companies can improve the efficiency and effectiveness of their shutdown processes.

Conclusion

The shutdown process in oil and gas is a critical operation that ensures the safety, efficiency, and longevity of equipment and facilities. By understanding the key stages of the shutdown process and leveraging digital workflows, industry professionals can streamline their shutdown activities and address the challenges associated with shutdowns. FAT FINGER’s digital workflows provide a centralized platform for task management, resource allocation, and real-time monitoring, helping oil and gas companies improve the efficiency and effectiveness of their shutdown processes. Create a shutdown and turnaround workflow for free on FAT FINGER or request a demo to see how our digital workflows can streamline your shutdown process.