Key Takeaways:

- Essential Safety Components: Safety critical elements (SCEs) are vital for preventing major accidents and ensuring the safe operation of oil and gas facilities.

- Regular Maintenance and Inspection: Regular maintenance and inspection of SCEs are crucial for ensuring their reliability and effectiveness.

- Digital Management Tools: Utilizing digital tools like FAT FINGER enhances the management and monitoring of SCEs, ensuring compliance and operational safety.

Safety Critical Elements in Oil and Gas

The oil and gas industry is fraught with inherent risks and hazards. Ensuring safety is paramount, not only to protect human lives but also to safeguard the environment and assets. Safety critical elements (SCEs) play a crucial role in this regard.

This article delves into the importance of SCEs, their identification, and management, and how digital workflows like FAT FINGER can enhance safety protocols. Request a demo today to see how FAT FINGER can revolutionize your safety processes.

What Are Safety Critical Elements?

Safety critical elements are components, systems, or procedures whose failure could lead to a major accident or significantly worsen its consequences. These elements are integral to maintaining the safety and integrity of oil and gas operations. They include physical equipment, control systems, and operational procedures.

Examples of Safety Critical Elements in oil and gas

Safety Critical Elements (SCEs) in the oil and gas industry are essential components, systems, or processes whose failure could result in a major accident, such as an explosion, fire, or significant environmental damage.

Examples of these elements include:

Blowout preventers (BOPs), which are crucial for controlling unexpected surges of oil or gas during drilling operations.

Emergency shutdown systems designed to halt operations swiftly in the event of a detected anomaly.

Fire and gas detection systems are another vital SCE, providing early warnings of hazardous conditions and triggering safety protocols to mitigate risks.

Additionally, pressure relief valves play a critical role in preventing over-pressurization of vessels and pipelines, thereby averting potential ruptures.

Lastly, structural integrity of platforms and rigs, ensured through regular inspections and maintenance, also constitutes a safety critical element, as any structural failure could lead to catastrophic outcomes.

Collectively, these elements are integral to maintaining the operational safety and environmental stewardship of oil and gas activities.

The Importance of Identifying Safety Critical Elements

Identifying SCEs is the first step in mitigating risks. Failure to recognize these elements can lead to catastrophic events. For instance, the Deepwater Horizon disaster in 2010 highlighted the dire consequences of inadequate safety measures.

Proper identification ensures that these elements receive the necessary attention and maintenance.

Steps to Identify Safety Critical Elements

The first step involves conducting Hazard Identification (HAZID) studies, which systematically identify potential hazards associated with specific processes or operations.

Secondly, perform a comprehensive risk assessment to evaluate the likelihood and potential impact of these identified hazards, thereby prioritizing the elements that require stringent controls.

Third, analyze historical incident to gain insights into past failures and near-misses, helping to pinpoint recurring issues and vulnerabilities within systems.

Additionally, engage with experienced personnel with knowledge and practical expertise to gain their valuable perspectives and nuanced understanding.

Together, these steps provide a robust framework for proactively safeguarding operations and ensuring regulatory compliance.

Managing Safety Critical Elements

Once identified, managing SCEs involves regular inspections, maintenance, and testing. This ensures that they function correctly when needed. Traditional methods of managing SCEs can be cumbersome and prone to human error.

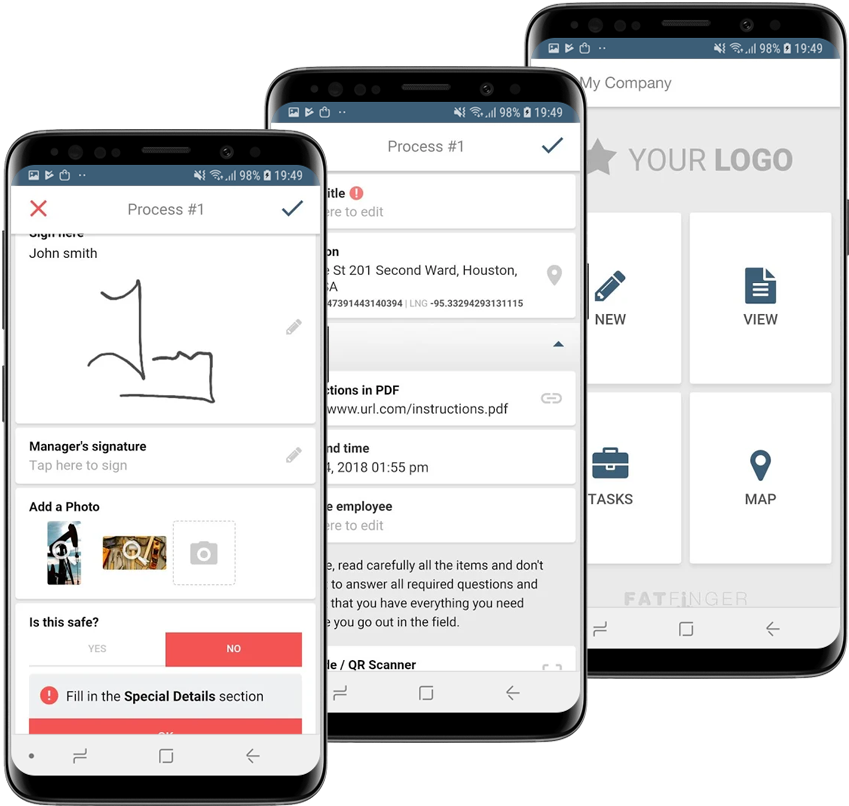

This is where digital solutions like FAT FINGER come into play. With FAT FINGER, you can create and deploy customized workflows in mere minutes.

Challenges of Managing SCEs

Managing Safety Critical Elements (SCEs) presents several challenges.

One major issue is the reliance on manual documentation and record-keeping, which is not only time-consuming but also prone to errors and omissions.

Inconsistent inspection schedules further exacerbate the problem, leading to potential oversights and unaddressed safety concerns.

More so, human error in reporting can distort the accuracy of safety data, compromising the integrity of safety assessments and corrective actions.

Additionally, the lack of real-time data hampers the ability to make timely and informed decisions, delaying critical interventions that could prevent accidents or mitigate risks.

Addressing these challenges requires the integration of automated systems and real-time monitoring solutions like FAT FINGER to enhance accuracy, consistency, and responsiveness.

Enhancing Safety with FAT FINGER Digital Workflows

FAT FINGER offers a suite of digital workflows designed to streamline safety processes in the oil and gas industry. These workflows ensure that SCEs are managed efficiently, reducing the risk of accidents and improving overall safety.

Take 5 Safety

The Take 5 Safety checklist encourages workers to take five minutes to assess potential hazards before starting a task. This proactive approach helps in identifying and mitigating risks early on. FAT FINGER’s digital Take 5 Safety checklist ensures that this process is consistently followed, with real-time data capture and reporting.

Near Miss Reporting

Near misses are often precursors to major incidents. Reporting and analyzing near misses can provide valuable insights into potential hazards. FAT FINGER’s Near Miss Reporting workflow simplifies this process, allowing workers to report near misses quickly and efficiently. This data is then analyzed to prevent future incidents.

Job Hazard Analysis

Job Hazard Analysis (JHA) involves identifying potential hazards associated with specific tasks and implementing measures to mitigate them. FAT FINGER’s JHA workflow ensures that this analysis is thorough and documented, providing a clear record of identified hazards and mitigation measures.

Risk Assessment

Risk assessments are crucial in identifying and evaluating risks associated with various operations. FAT FINGER’s Risk Assessment workflow provides a structured approach to this process, ensuring that all potential risks are considered and appropriate measures are implemented.

Incident Reporting in the Workplace

Timely and accurate incident reporting is essential for effective incident management. FAT FINGER’s Incident Reporting workflow streamlines this process, ensuring that all incidents are reported promptly and accurately. This allows for quick response and analysis, preventing recurrence.

Journey Report

In the oil and gas industry, transportation of personnel and equipment poses significant risks. The Journey Report workflow in FAT FINGER ensures that all journeys are planned and monitored, with potential hazards identified and mitigated. This enhances the safety of personnel and assets during transportation.

Case Studies: Real-World Applications of FAT FINGER

Several companies in the oil and gas industry have successfully implemented FAT FINGER to enhance their safety protocols. For instance, a leading oil company reported a 30% reduction in near misses after adopting FAT FINGER’s Near Miss Reporting workflow. Another company saw a 25% improvement in compliance with safety inspections using the Take 5 Safety checklist.

Statistics Highlighting the Importance of SCEs

According to the International Association of Oil & Gas Producers (IOGP), over 60% of major incidents in the industry are linked to failures in safety critical elements. This underscores the importance of effective SCE management. Additionally, companies that have implemented digital workflows like FAT FINGER have reported a 40% reduction in safety-related incidents.

Conclusion

Safety critical elements are vital to ensuring the safety and integrity of oil and gas operations. Proper identification and management of these elements can prevent catastrophic incidents. Digital workflows like FAT FINGER offer a robust solution to streamline safety processes, reduce human error, and enhance overall safety. Create a safety workflow for free on FAT FINGER or request a demo today to see how it can transform your safety protocols.

FAQs for Understanding Safety Critical Elements in Oil and Gas

Q: What are Safety Critical Elements (SCEs) in the oil and gas industry?

Safety critical elements (SCEs) are components of an oil and gas facility that are essential for preventing major accidents and ensuring safe operation. These include equipment and systems designed to control and mitigate hazardous events.

Q: Why is the management of SCEs important?

Managing SCEs is crucial because they play a key role in preventing accidents and ensuring the safety of personnel, the environment, and the facility. Effective management ensures that these elements are reliable and function as intended.

Q: How can regular maintenance and inspection improve the reliability of SCEs?

Regular maintenance and inspection help identify potential issues with SCEs before they lead to failures. Routine checks and timely repairs ensure that SCEs remain in good working condition, enhancing overall safety.

Q: What role do digital tools play in managing SCEs?

Digital tools like FAT FINGER streamline the management and monitoring of SCEs. These tools provide checklists, inspection reports, and real-time data, ensuring that SCEs are maintained and compliant with safety standards.

Q: Can you give examples of common SCEs in the oil and gas industry?

Common SCEs include blowout preventers, emergency shutdown systems, fire and gas detection systems, and pressure relief devices. These elements are critical for controlling and mitigating hazardous events in oil and gas operations.

Q: How does FAT FINGER’s Incident Reporting workflow enhance the management of SCEs?

FAT FINGER’s Incident Reporting workflow enables real-time reporting of issues related to SCEs. This ensures that any problems are promptly addressed, maintaining the integrity and reliability of these critical elements.

Q: What is the importance of training personnel on SCEs?

Training personnel on SCEs ensures that they understand the importance of these elements and how to operate and maintain them correctly. Well-trained staff can identify and address issues with SCEs more effectively, enhancing overall safety.

Q: How can risk assessments improve the management of SCEs?

Risk assessments help identify potential hazards and evaluate the effectiveness of SCEs in mitigating these risks. By regularly assessing risks, companies can ensure that SCEs are adequately maintained and updated to address evolving threats.

Q: What are the benefits of using digital checklists for SCE inspections?

Digital checklists ensure that inspections are thorough and standardized. They provide a systematic approach to checking SCEs, making it easier to identify and rectify issues, and ensuring that nothing is overlooked.

Q: How does the integration of IoT devices enhance the monitoring of SCEs?

The integration of IoT devices allows for real-time monitoring of SCEs, providing continuous data on their performance. This enables proactive maintenance and quicker response to any issues, ensuring the reliability and effectiveness of these critical elements.