Asset management is a critical component of any organization that aims to maximize the value of its assets while minimizing risks and costs. Understanding the core principles of asset management can help businesses streamline operations, improve efficiency, and achieve long-term sustainability. In this article, we will explore three fundamental principles of asset management and how leveraging digital workflows, such as those offered by FAT FINGER, can enhance these principles. Request a demo today to see how FAT FINGER can revolutionize your asset management processes.

1. Lifecycle Management

Lifecycle management is the cornerstone of effective asset management. It involves overseeing an asset from its acquisition to its disposal, ensuring that it delivers maximum value throughout its lifecycle. This principle encompasses several stages, including planning, acquisition, operation, maintenance, and disposal.

Planning

Effective planning is crucial for making informed decisions about asset acquisition and utilization. It involves assessing the needs of the organization, forecasting future requirements, and budgeting for asset-related expenses. For example, a manufacturing company might plan for the acquisition of new machinery based on production forecasts and market demand.

Acquisition

Acquisition involves procuring assets that meet the organization’s needs and budget. This stage includes evaluating suppliers, negotiating contracts, and ensuring that the assets comply with regulatory standards. For instance, a hospital might acquire medical equipment from reputable suppliers to ensure patient safety and compliance with healthcare regulations.

Operation and Maintenance

Once assets are acquired, they must be operated and maintained efficiently to maximize their value. This includes regular inspections, preventive maintenance, and timely repairs. For example, a transportation company might schedule regular maintenance for its fleet to prevent breakdowns and ensure safety.

Disposal

Disposal involves retiring assets that are no longer useful or cost-effective. This stage includes decommissioning, recycling, or selling the assets. For instance, an IT company might dispose of outdated hardware by recycling it in an environmentally friendly manner.

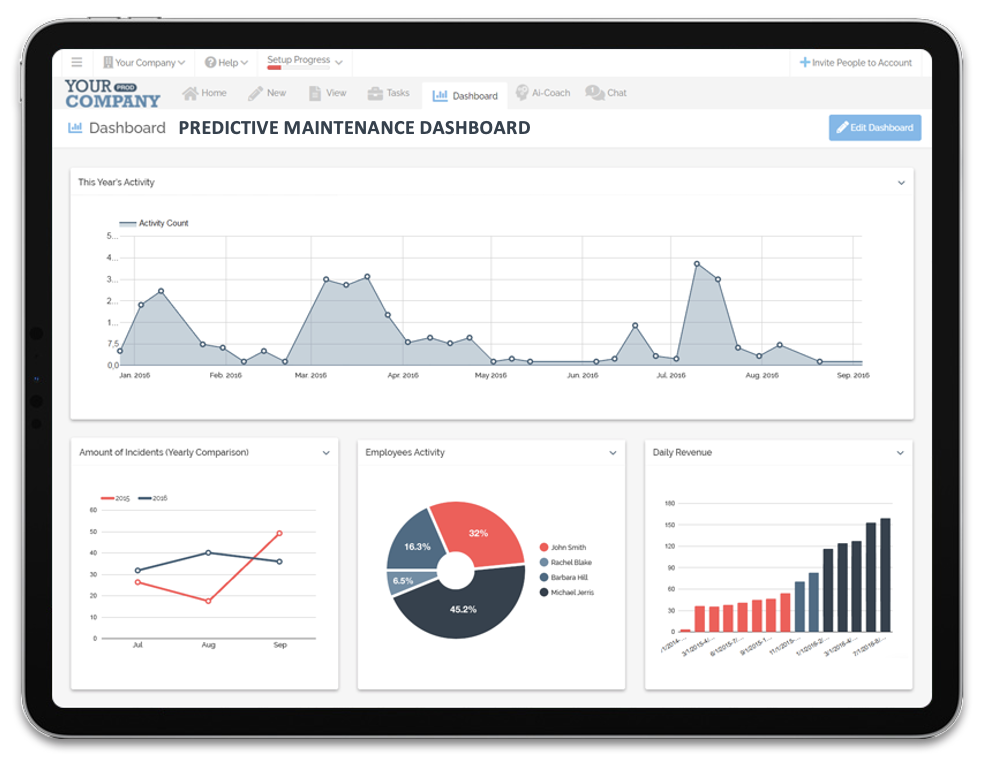

FAT FINGER’s digital workflows can streamline lifecycle management by providing real-time data, automated maintenance schedules, and comprehensive asset tracking. This ensures that assets are managed efficiently throughout their lifecycle, reducing downtime and costs.

2. Risk Management

Risk management is another essential principle of asset management. It involves identifying, assessing, and mitigating risks associated with asset ownership and operation. Effective risk management ensures that assets are protected from potential threats, minimizing financial losses and operational disruptions.

Risk Identification

Identifying risks involves recognizing potential threats that could impact asset performance. This includes physical risks (e.g., equipment failure), financial risks (e.g., budget overruns), and regulatory risks (e.g., non-compliance with laws). For example, a utility company might identify risks related to aging infrastructure and natural disasters.

Risk Assessment

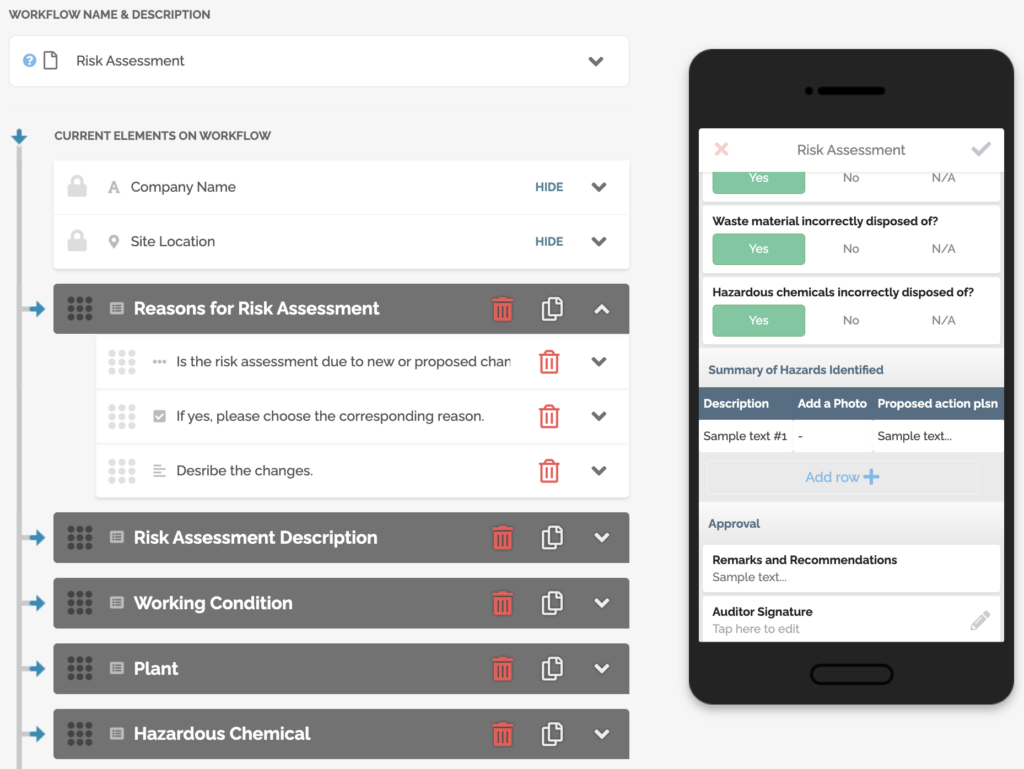

Assessing risks involves evaluating the likelihood and impact of identified threats. This helps organizations prioritize risks and allocate resources effectively. For instance, a chemical plant might assess the risk of equipment failure by analyzing historical data and conducting safety audits.

Risk Mitigation

Mitigating risks involves implementing measures to reduce the likelihood and impact of potential threats. This includes preventive maintenance, safety protocols, and insurance coverage. For example, an oil and gas company might implement regular inspections and emergency response plans to mitigate the risk of spills and accidents.

FAT FINGER’s digital workflows can enhance risk management by providing real-time monitoring, automated alerts, and comprehensive risk assessments. This enables organizations to proactively address potential threats and ensure the safety and reliability of their assets.

3. Performance Optimization

Performance optimization is the third key principle of asset management. It involves maximizing the efficiency and effectiveness of assets to achieve organizational goals. This principle focuses on improving asset performance, reducing costs, and enhancing productivity.

Performance Monitoring

Monitoring asset performance involves tracking key performance indicators (KPIs) to assess efficiency and effectiveness. This includes metrics such as uptime, utilization, and maintenance costs. For example, a manufacturing plant might monitor the performance of its machinery to identify areas for improvement.

Continuous Improvement

Continuous improvement involves regularly evaluating and enhancing asset performance. This includes implementing best practices, adopting new technologies, and optimizing processes. For instance, a logistics company might adopt advanced tracking systems to improve fleet management and reduce delivery times.

Cost Management

Managing costs involves optimizing asset-related expenses to achieve cost savings. This includes reducing maintenance costs, minimizing downtime, and extending asset lifespan. For example, a construction company might implement preventive maintenance programs to reduce equipment repair costs and extend the lifespan of its machinery.

FAT FINGER’s digital workflows can support performance optimization by providing real-time data, predictive analytics, and automated reporting. This enables organizations to monitor asset performance, identify areas for improvement, and implement cost-saving measures effectively.

Case Studies: Real-World Applications

To illustrate the effectiveness of these principles, let’s explore a few real-world case studies where organizations have successfully implemented asset management strategies with the help of FAT FINGER.

Case Study 1: Manufacturing Plant

A manufacturing plant faced frequent equipment breakdowns, leading to production delays and increased maintenance costs. By implementing FAT FINGER’s digital workflows, the plant was able to schedule regular preventive maintenance, monitor equipment performance in real-time, and receive automated alerts for potential issues. As a result, the plant reduced downtime by 30% and maintenance costs by 20%.

Case Study 2: Utility Company

A utility company struggled with aging infrastructure and regulatory compliance. By leveraging FAT FINGER’s risk management tools, the company conducted comprehensive risk assessments, implemented safety protocols, and monitored infrastructure health in real-time. This enabled the company to address potential threats proactively, ensuring regulatory compliance and reducing the risk of infrastructure failures.

Case Study 3: Logistics Company

A logistics company faced challenges in fleet management, including high fuel costs and inefficient route planning. By adopting FAT FINGER’s performance optimization tools, the company was able to track fleet performance, optimize routes, and implement fuel-saving measures. This resulted in a 15% reduction in fuel costs and a 10% improvement in delivery times.

Conclusion

Understanding and implementing the core principles of asset management—lifecycle management, risk management, and performance optimization—can significantly enhance an organization’s efficiency, productivity, and sustainability. By leveraging digital workflows like those offered by FAT FINGER, businesses can streamline their asset management processes, reduce costs, and mitigate risks effectively.

Ready to take your asset management to the next level? Create a mobile asset inspection workflow for free on FAT FINGER.