Key Takeaways

- Importance of PPE: Recognize the essential role of PPE in protecting workers in the hazardous oil and gas industry.

- Regulatory Compliance: Adhere to OSHA and ANSI standards to ensure PPE effectiveness.

- Types of PPE: Use the appropriate PPE for specific tasks to mitigate risks.

- Challenges in Compliance: Address training gaps, maintenance issues, and resistance to PPE usage.

- Digital Solutions: Leverage FAT FINGER’s digital workflows for efficient and effective PPE compliance.

- Continuous Improvement: Use tools like Take 5 Safety, Near Miss Reporting, and Job Hazard Analysis to proactively manage and improve safety protocols.

Personal Protective Equipment (PPE) Standards in Oil and Gas

In the high-risk environment of the oil and gas industry, Personal Protective Equipment (PPE) is essential for safeguarding workers. Adhering to stringent PPE standards is not just a regulatory requirement but a moral obligation to ensure the safety and well-being of employees.

This article delves into the critical aspects of PPE standards in the oil and gas sector, highlighting the importance of compliance, and introduces FAT FINGER digital workflows as a robust solution to enhance safety protocols.

Request a demo today to see how FAT FINGER can revolutionize your safety processes.

The Importance of PPE in Oil and Gas

The oil and gas industry is fraught with hazards, from chemical exposures to physical injuries. PPE serves as the last line of defense against these dangers. Proper PPE usage can mean the difference between a minor incident and a catastrophic event.

Types of PPE in Oil and Gas

Different tasks require different types of PPE. Here are some common types:

- Helmets: Protect against head injuries from falling objects.

- Gloves: Shield hands from chemicals, cuts, and abrasions.

- Goggles: Guard eyes against chemical splashes and debris.

- Respirators: Prevent inhalation of harmful gases and particles.

- Protective Clothing: Offers resistance to fire, chemicals, and extreme temperatures.

Regulatory Standards for PPE

Compliance with regulatory standards is crucial for ensuring the effectiveness of PPE. Organizations like OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) set stringent guidelines for PPE usage.

OSHA Standards

OSHA mandates that employers provide PPE that is properly maintained and fits well. They also require regular training for employees on the correct use of PPE.

ANSI Standards

ANSI provides detailed specifications for different types of PPE, ensuring they meet minimum performance requirements. For example, ANSI Z87.1 sets standards for eye protection, while ANSI Z89.1 covers head protection.

Challenges in PPE Compliance

Despite the clear guidelines, many companies struggle with PPE compliance. Common challenges include:

- Lack of Training: Employees may not know how to use PPE correctly.

- Inadequate Maintenance: PPE that is not regularly inspected and maintained can fail.

- Resistance to Use: Some workers may find PPE uncomfortable and opt not to use it.

FAT FINGER: A Digital Solution for PPE Compliance

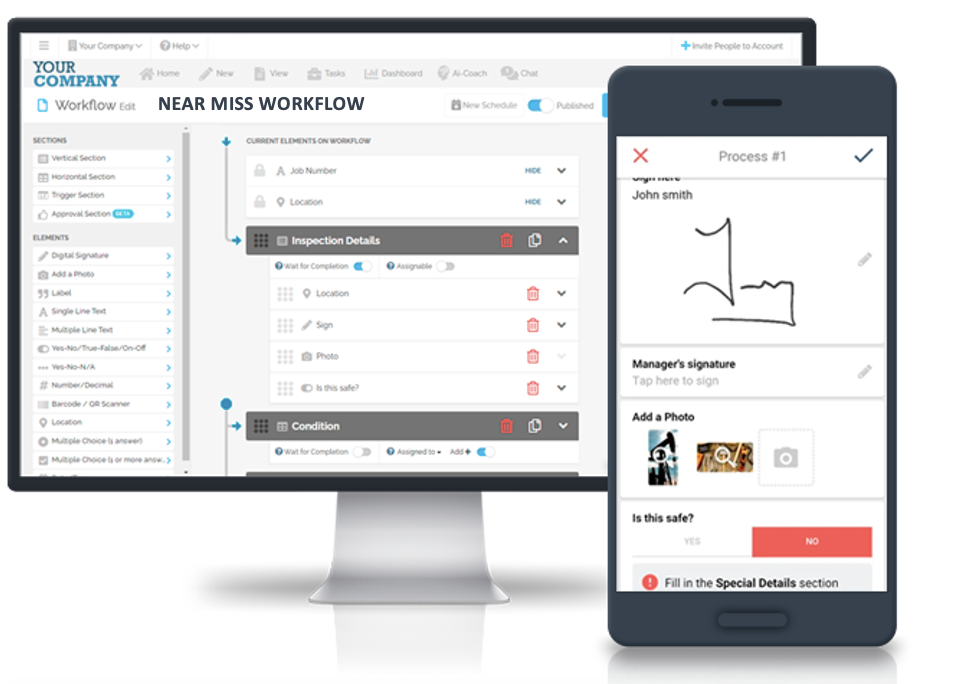

FAT FINGER offers a suite of digital workflows designed to streamline safety processes and ensure PPE compliance.

Here are six powerful safety checklists that can transform your safety protocols:

1. Take 5 Safety

The Take 5 Safety checklist encourages workers to take five minutes before starting a task to assess potential hazards. This proactive approach can identify PPE needs and ensure that all necessary equipment is in place.

2. Near Miss Reporting

Near Miss Reporting allows workers to document incidents that could have resulted in injury. This data can be analyzed to identify trends and improve PPE usage, preventing future accidents.

3. Job Hazard Analysis

Job Hazard Analysis (JHA) involves a detailed examination of each task to identify potential hazards and determine the appropriate PPE. FAT FINGER’s JHA checklist ensures that no detail is overlooked.

4. Risk Assessment

Risk Assessment is crucial for identifying and mitigating risks. FAT FINGER’s digital workflow makes it easy to conduct thorough risk assessments, ensuring that all PPE requirements are met.

5. Incident Reporting

Incident Reporting is essential for tracking and analyzing workplace accidents. FAT FINGER’s incident reporting tool allows for quick and accurate documentation, helping to improve PPE protocols and prevent future incidents.

6. Journey Report

The Journey Report checklist ensures that all safety measures, including PPE, are in place for workers traveling to and from job sites. This comprehensive approach ensures that safety is maintained at all times.

Case Studies: Success Stories with FAT FINGER

Several companies in the oil and gas industry have successfully implemented FAT FINGER’s digital workflows to enhance their PPE compliance. For example, a leading oil company reduced its incident rate by 30% within six months of adopting FAT FINGER’s safety checklists.

Example 1: Improved PPE Compliance

A mid-sized oil company struggled with PPE compliance due to inadequate training and maintenance. After implementing FAT FINGER’s Take 5 Safety and Job Hazard Analysis checklists, they saw a significant improvement in PPE usage and a reduction in workplace injuries.

Example 2: Enhanced Risk Assessment

Another company used FAT FINGER’s Risk Assessment and Incident Reporting tools to identify gaps in their PPE protocols. This led to the implementation of more effective safety measures and a 25% decrease in near-miss incidents.

Conclusion

Ensuring PPE compliance in the oil and gas industry is a complex but essential task. By adhering to regulatory standards and leveraging digital solutions like FAT FINGER, companies can significantly improve their safety protocols.

The six powerful safety checklists offered by FAT FINGER provide a comprehensive approach to managing PPE and other safety measures. Create a safety workflow for free on FAT FINGER or request a demo today to see how these tools can benefit your organization.

FAQs About Personal Protective Equipment (PPE) Standards in Oil and Gas

Q: What is Personal Protective Equipment (PPE)?

PPE refers to the protective clothing, helmets, goggles, gloves, and other equipment designed to protect workers from injuries and illnesses in hazardous environments.

Q: Why is PPE important in the oil and gas industry?

The oil and gas industry is fraught with hazards such as chemical exposures, physical injuries, and extreme temperatures. Proper PPE is essential for safeguarding workers and preventing serious accidents.

Q: What types of PPE are commonly used in the oil and gas industry?

- Helmets: Protect against head injuries from falling objects.

- Gloves: Shield hands from chemicals, cuts, and abrasions.

- Goggles: Guard eyes against chemical splashes and debris.

- Respirators: Prevent inhalation of harmful gases and particles.

- Protective Clothing: Offers resistance to fire, chemicals, and extreme temperatures.

Q: What are the regulatory standards for PPE?

Organizations like OSHA and ANSI set stringent guidelines for PPE usage, ensuring that equipment meets performance requirements and is properly maintained and used correctly.

Q: What challenges do companies face in PPE compliance?

Common challenges include lack of training, inadequate maintenance, and resistance to use due to discomfort.

Q: How can FAT FINGER help with PPE compliance?

FAT FINGER offers digital workflows that streamline safety processes, ensuring PPE is used correctly and consistently. Tools like Take 5 Safety, Near Miss Reporting, and Job Hazard Analysis help identify and mitigate risks.

Q: How can I implement FAT FINGER in my workplace?

Request a demo through the FAT FINGER website to see how our digital workflows can enhance PPE compliance and safety practices.

Q: What are the main benefits of using FAT FINGER for PPE compliance?

FAT FINGER improves operational efficiency, ensures consistent PPE usage, enhances safety compliance, and reduces the likelihood of workplace accidents through its digital solutions.