Asset inspections are essential for ensuring the safety, reliability, and longevity of equipment. However, traditional inspection methods can be time-consuming and costly.

This article delves into strategies for enhancing the cost and time efficiency of asset inspections, providing valuable insights and practical solutions. Request a demo of FAT FINGER to see how digital workflows can revolutionize your asset inspection process.

The Importance of Asset Inspections

Asset inspections are vital for identifying potential issues before they escalate into costly repairs or catastrophic failures. Regular inspections help in:

- Ensuring compliance with safety regulations

- Extending the lifespan of equipment

- Minimizing downtime

- Improving overall operational efficiency

Despite their importance, traditional inspection methods often fall short in terms of efficiency. Manual data entry, paper-based records, and lack of real-time updates can lead to delays and errors.

Challenges in Traditional Asset Inspection Methods

Traditional asset inspection methods come with several challenges that hinder efficiency:

- Time-Consuming Processes: Manual inspections and data entry are labor-intensive and prone to human error.

- High Costs: The need for specialized personnel and equipment can drive up costs.

- Data Inaccuracy: Paper-based records are susceptible to errors and can be difficult to manage.

- Lack of Real-Time Updates: Delays in data processing can lead to outdated information and slow decision-making.

These challenges highlight the need for a more efficient approach to asset inspections. This is where digital solutions like FAT FINGER come into play.

Optimizing Asset Inspections with Digital Workflows

Digital workflows offer a transformative solution to the inefficiencies of traditional asset inspections. By leveraging technology, organizations can streamline their inspection processes, reduce costs, and improve accuracy. Here are some key benefits of digital workflows:

- Automated Data Collection: Digital tools enable automated data collection, reducing the need for manual entry and minimizing errors.

- Real-Time Updates: Digital platforms provide real-time updates, ensuring that all stakeholders have access to the latest information.

- Cost Savings: By reducing the need for specialized personnel and equipment, digital workflows can significantly lower inspection costs.

- Improved Data Accuracy: Digital records are more accurate and easier to manage than paper-based records.

FAT FINGER is a leading digital workflow solution that can help organizations optimize their asset inspection processes. Let’s explore how FAT FINGER addresses the pain points of traditional inspections.

Case Study: Enhancing Efficiency with FAT FINGER

Consider a manufacturing company that struggled with time-consuming and costly asset inspections. By implementing FAT FINGER, the company achieved remarkable improvements:

- Reduced Inspection Time: The company reduced inspection time by 50% through automated data collection and real-time updates.

- Cost Savings: By eliminating the need for paper-based records and manual data entry, the company saved thousands of dollars annually.

- Improved Data Accuracy: Digital records ensured accurate and up-to-date information, leading to better decision-making.

This case study demonstrates the tangible benefits of using FAT FINGER for asset inspections. The platform’s user-friendly interface and powerful features make it an ideal solution for organizations looking to enhance efficiency.

Key Features of FAT FINGER for Asset Inspections

FAT FINGER offers a range of features designed to optimize asset inspections:

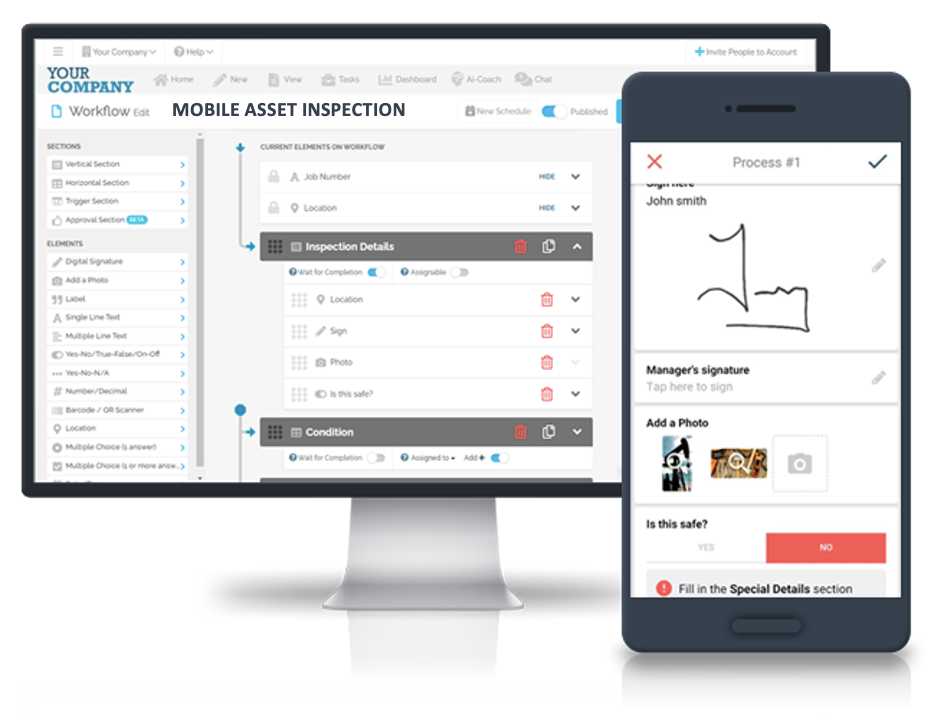

- Customizable Inspection Templates: Create and customize inspection templates to suit your specific needs.

- Automated Workflows: Automate repetitive tasks and streamline the inspection process.

- Real-Time Data Sync: Ensure that all stakeholders have access to the latest information with real-time data synchronization.

- Mobile Accessibility: Conduct inspections from anywhere using mobile devices.

- Comprehensive Reporting: Generate detailed reports to gain insights and make informed decisions.

These features make FAT FINGER a powerful tool for optimizing asset inspections and achieving cost and time efficiency.

Implementing FAT FINGER: A Step-by-Step Guide

Implementing FAT FINGER for asset inspections is a straightforward process:

- Step 1: Request a Demo: Start by requesting a demo to see how FAT FINGER can benefit your organization.

- Step 2: Customize Templates: Create and customize inspection templates to match your specific requirements.

- Step 3: Train Your Team: Provide training to your team to ensure they are comfortable using the platform.

- Step 4: Conduct Inspections: Begin conducting inspections using FAT FINGER’s mobile app and automated workflows.

- Step 5: Analyze Data: Use FAT FINGER’s reporting features to analyze data and make informed decisions.

By following these steps, you can seamlessly integrate FAT FINGER into your asset inspection process and start reaping the benefits of digital workflows.

Conclusion

Optimizing the asset inspection process is essential for achieving cost and time efficiency. Traditional inspection methods are often plagued by inefficiencies, leading to increased costs and delays. Digital workflows, such as those offered by FAT FINGER, provide a powerful solution to these challenges. By automating data collection, providing real-time updates, and improving data accuracy, FAT FINGER helps organizations streamline their inspection processes and achieve significant cost savings.

Ready to revolutionize your asset inspection process? Create a mobile asset inspection workflow for free on FAT FINGER or request a demo today. Experience the benefits of digital workflows and take your asset inspections to the next level.