Key Takeaways:

- Critical Safety Gear: Essential safety equipment, including PPE and fire protection systems, is crucial for safeguarding workers in the oil and gas industry.

- Comprehensive Safety Measures: A well-rounded safety program includes equipment for head, eye, face, hearing, respiratory, hand, body, and foot protection.

- Advanced Safety Solutions: Digital tools like FAT FINGER enhance the implementation and management of safety equipment, ensuring compliance and effectiveness.

Digital Safety Measures in the Oil and Gas Industry

The oil and gas industry is one of the most hazardous sectors globally. Ensuring safety is paramount to protect workers, the environment, and assets. This article delves into comprehensive digital safety measures in the oil and gas industry, highlighting the importance of robust safety protocols. We will also explore how FAT FINGER’s digital workflows can enhance safety practices.

Request a demo today to see how FAT FINGER can revolutionize your safety measures.

The Importance of Safety in the Oil and Gas Industry

Safety in the oil and gas industry is critical due to the high-risk nature of operations. From drilling to transportation, each phase presents unique hazards. Implementing comprehensive safety measures can prevent accidents, reduce downtime, and save lives.

High-Risk Operations

Oil and gas operations involve high-pressure systems, flammable materials, and heavy machinery. These factors contribute to the industry’s inherent risks. For instance, the Deepwater Horizon disaster in 2010 highlighted the catastrophic consequences of safety lapses.

Environmental Impact

Accidents in the oil and gas industry can lead to significant environmental damage. Oil spills, gas leaks, and explosions can devastate ecosystems and harm wildlife. Effective safety measures are essential to mitigate these risks.

Digital Safety Measures in the Oil and Gas Industry

Implementing comprehensive safety measures involves several key components. These measures ensure that risks are identified, assessed, and mitigated effectively.

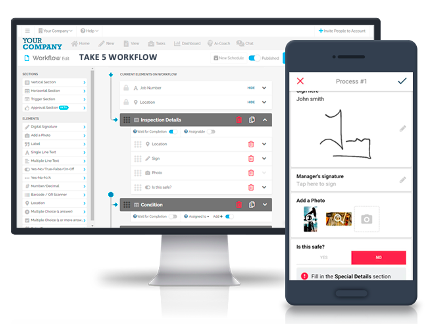

Take 5 Safety

Take 5 Safety is a proactive approach to hazard identification. Workers take five minutes to assess their surroundings and identify potential hazards before starting a task. This simple yet effective measure can prevent accidents and promote a safety-first culture.

- Identify hazards

- Assess risks

- Implement controls

- Monitor and review

FAT FINGER’s Take 5 Safety checklist ensures that workers consistently follow safety protocols. The digital tool simplifies hazard identification and risk assessment, promoting a safety-first culture.

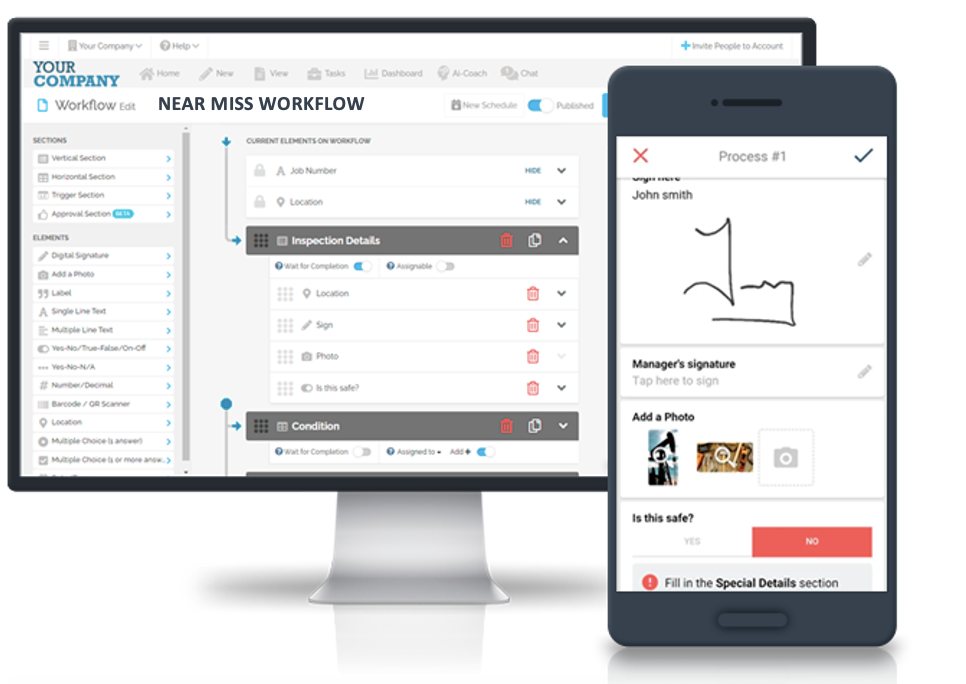

Near Miss Reporting

Near miss reporting involves documenting incidents that could have resulted in accidents but did not. This practice helps identify potential hazards and prevent future incidents.

- Encourage reporting

- Analyze data

- Implement corrective actions

FAT FINGER’s Near Miss Reporting tool simplifies data collection and analysis. Organizations can quickly identify potential hazards and implement corrective actions, preventing future incidents.

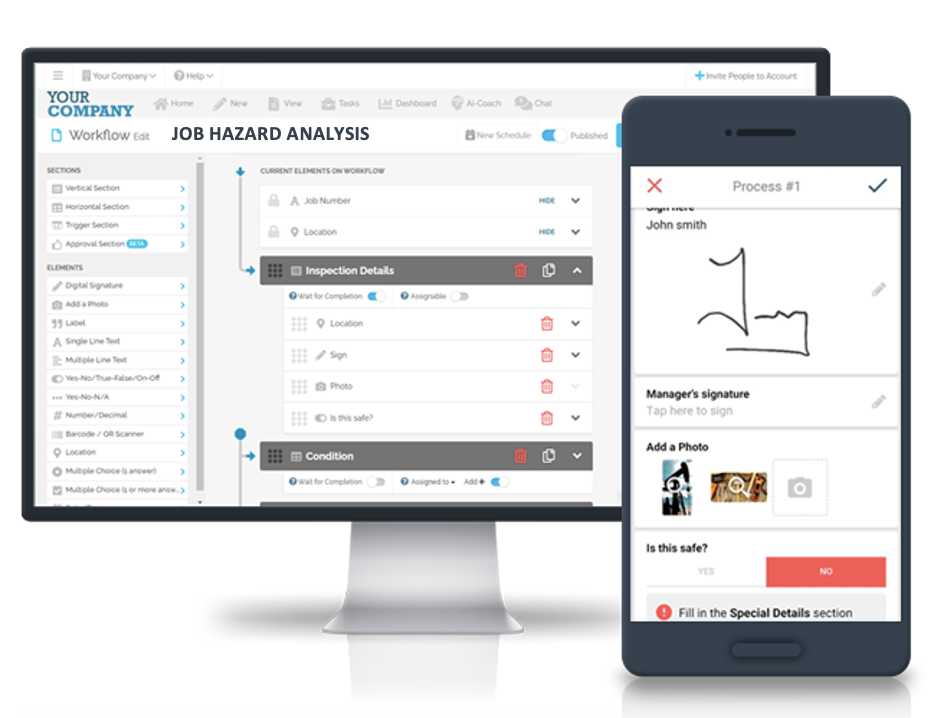

Job Hazard Analysis

Job Hazard Analysis (JHA) involves identifying and mitigating risks associated with specific tasks. This process ensures that workers understand the hazards and take appropriate precautions.

- Break down tasks

- Identify hazards

- Determine controls

FAT FINGER’s JHA checklist provides a structured approach to hazard analysis. The tool ensures that workers understand the hazards associated with specific tasks and take appropriate precautions.

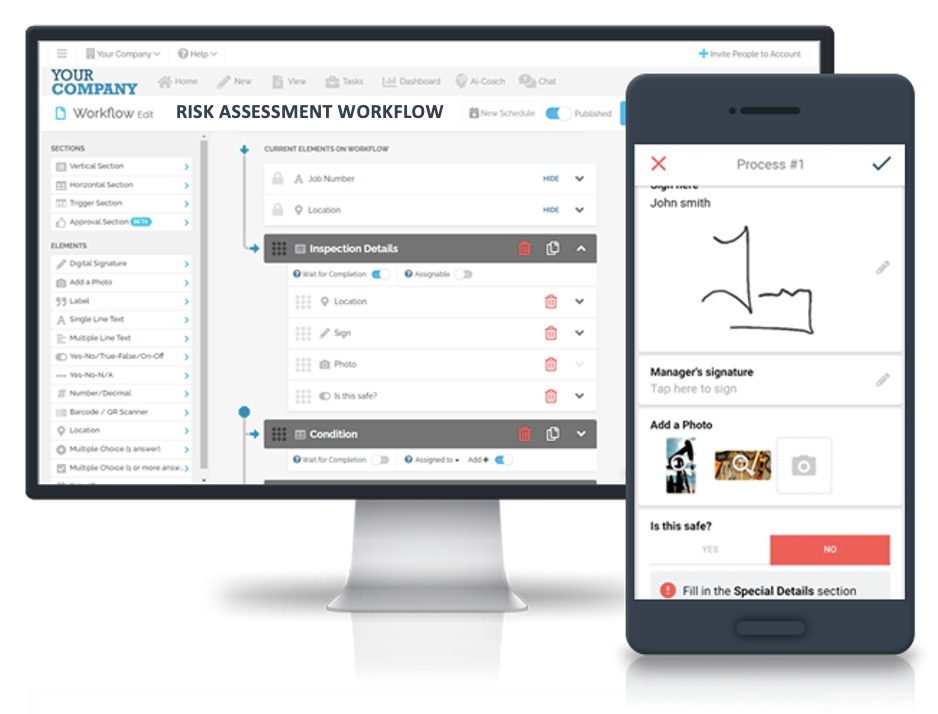

Risk Assessment

Risk assessment is a systematic process of evaluating potential hazards and implementing controls. This measure is crucial for preventing accidents and ensuring compliance with safety regulations.

- Identify hazards

- Evaluate risks

- Implement controls

- Monitor effectiveness

FAT FINGER’s Risk Assessment tool offers a comprehensive solution for managing risks. The digital tool streamlines the risk assessment process, ensuring that organizations can effectively evaluate and mitigate hazards.

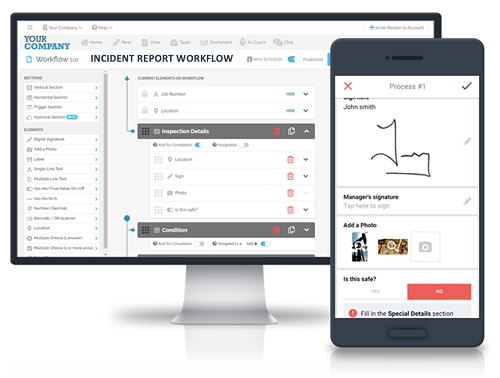

Incident Reporting in the Workplace

Incident reporting involves documenting accidents and near misses. This practice helps organizations identify trends, implement corrective actions, and improve safety protocols.

- Encourage reporting

- Analyze incidents

- Implement corrective actions

FAT FINGER’s Incident Reporting tool streamlines the reporting process. The digital tool ensures that incidents are documented and addressed promptly, helping organizations improve safety protocols.

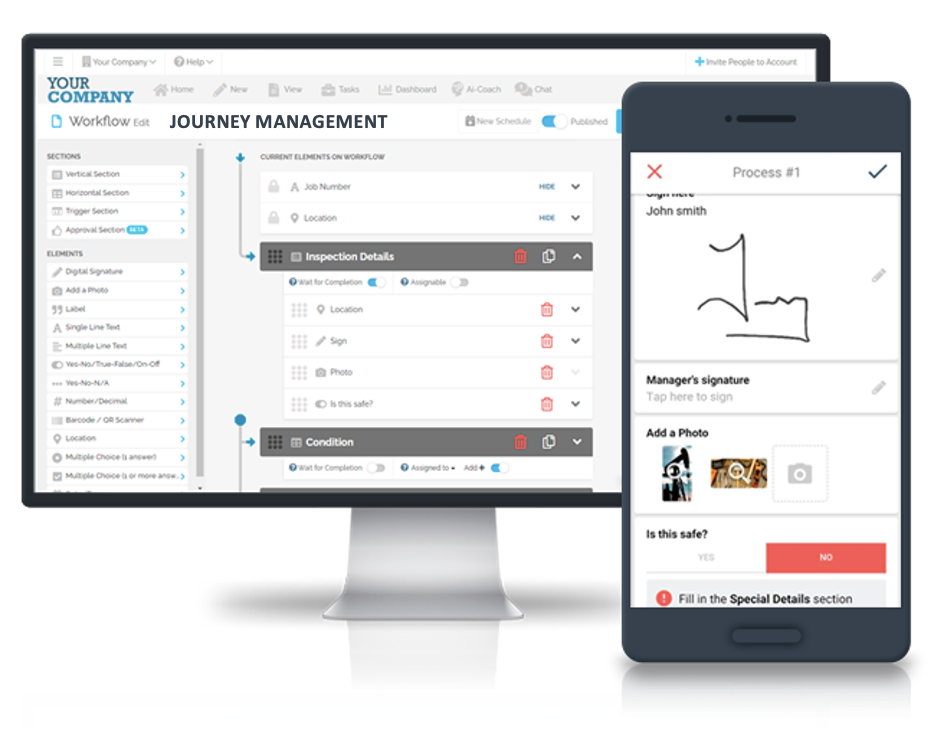

Journey Report

Journey reports document the details of transportation activities, including routes, hazards, and incidents. This measure is essential for ensuring the safety of workers during transportation.

- Document routes

- Identify hazards

- Report incidents

FAT FINGER’s Journey Report tool provides a comprehensive solution for managing transportation safety. The digital tool ensures that routes, hazards, and incidents are documented, promoting the safety of workers during transportation.

Case Studies and Statistics

Several case studies and statistics highlight the importance of comprehensive safety measures in the oil and gas industry.

Deepwater Horizon Disaster

The Deepwater Horizon disaster in 2010 resulted in 11 fatalities and a massive oil spill. The incident underscored the need for robust safety protocols and effective risk management.

Statistics on Workplace Accidents

According to the International Association of Oil & Gas Producers (IOGP), the industry recorded 25 fatalities in 2020. Implementing comprehensive safety measures can significantly reduce these numbers.

Conclusion

Comprehensive safety measures are essential in the oil and gas industry. Implementing robust safety protocols can prevent accidents, protect workers, and reduce environmental impact. FAT FINGER’s digital workflows offer powerful solutions for enhancing safety measures.

FAQs for Essential Safety Equipment in the Oil and Gas Industry

Q: What is the significance of PPE in the oil and gas industry?

PPE is vital in safeguarding workers from numerous hazards such as chemical exposure, fire, explosions, and physical injuries. It ensures compliance with industry regulations and promotes a safer working environment.

Q: What types of head protection are essential for oil and gas workers?

Hard hats are mandatory for protecting workers from head injuries caused by falling objects or accidental impacts. They are designed to absorb shock and provide a barrier against electrical hazards.

Q: Why is eye and face protection crucial in this industry?

Safety goggles and face shields protect workers from chemical splashes, flying debris, and intense light, preventing eye injuries and facial burns, which are common risks in the oil and gas sector.

Q: How does hearing protection benefit workers in the oil and gas industry?

Exposure to high noise levels can lead to hearing loss. Earplugs and earmuffs reduce noise exposure and protect workers’ hearing, ensuring long-term auditory health.

Q: What role does respiratory protection play?

Respirators are necessary for workers exposed to harmful gases, vapors, and particulate matter. These devices filter out contaminants and provide clean air for breathing, crucial for maintaining respiratory health.

Q: What types of gloves are used for hand protection?

Various gloves, including chemical-resistant, cut-resistant, and heat-resistant gloves, protect workers’ hands from chemical burns, cuts, and abrasions, ensuring safety while handling hazardous materials.

Q: What is the importance of body protection?

Flame-resistant clothing is essential for workers exposed to fire and explosion hazards. These garments are designed to self-extinguish and prevent severe burns. High-visibility clothing also ensures workers are easily seen, reducing the risk of accidents.

Q: How do safety boots protect workers in the oil and gas industry?

Safety boots with steel toes and slip-resistant soles protect workers’ feet from heavy objects, sharp materials, and slippery surfaces, ensuring safe and secure footing.

Q: What are the benefits of using digital workflows for safety protocols?

Digital workflows, like those offered by FAT FINGER, streamline safety processes, enhance reporting accuracy, and ensure compliance with safety standards, significantly improving overall safety management.

Q: How can companies implement effective PPE and safety protocols?

Companies can implement effective PPE and safety protocols by training personnel, utilizing appropriate PPE, integrating digital workflows, and continuously monitoring and adjusting safety measures to align with industry standards and regulations.