The oil and gas industry is fraught with potential hazards, making safety a paramount concern. One of the key frameworks guiding safety protocols in this sector is the National Fire Protection Association (NFPA) standards. These standards are designed to minimize risks and ensure the safety of personnel, equipment, and the environment.

In this article, we will delve into the importance of NFPA standards in the oil and gas industry, explore specific standards, and discuss how digital workflows like FAT FINGER can enhance compliance and safety.

The Importance of NFPA Standards

NFPA standards are a set of guidelines developed to prevent fire and other hazards. They are widely recognized and adopted across various industries, including oil and gas. These standards cover a broad range of safety aspects, from fire prevention to emergency response.

Why NFPA Standards Matter

Compliance with NFPA standards is not just a regulatory requirement; it is a critical component of operational safety. Here are some reasons why these standards are indispensable:

- Risk Mitigation: NFPA standards help identify potential hazards and provide guidelines to mitigate them.

- Regulatory Compliance: Adhering to these standards ensures compliance with local, state, and federal regulations.

- Operational Efficiency: Implementing NFPA standards can lead to more efficient and safer operations.

- Reputation Management: Companies that comply with NFPA standards are viewed as responsible and trustworthy, enhancing their reputation.

Key NFPA Standards in the Oil and Gas Industry

Several NFPA standards are particularly relevant to the oil and gas sector. Understanding these standards is crucial for maintaining a safe working environment.

NFPA 30: Flammable and Combustible Liquids Code

NFPA 30 provides guidelines for the storage, handling, and use of flammable and combustible liquids. This standard is essential for preventing fires and explosions in facilities that store or process these liquids.

NFPA 58: Liquefied Petroleum Gas Code

NFPA 58 covers the safe storage, handling, transportation, and use of liquefied petroleum gas (LPG). Compliance with this standard is vital for preventing accidents involving LPG.

NFPA 70: National Electrical Code

NFPA 70 sets the standard for electrical installations, ensuring they are safe and reliable. This is particularly important in the oil and gas industry, where electrical systems are often exposed to harsh conditions.

NFPA 497: Classification of Flammable Liquids, Gases, or Vapors

NFPA 497 provides guidelines for classifying hazardous locations for electrical installations. This standard helps in identifying areas where flammable gases or vapors may be present, ensuring appropriate safety measures are in place.

Challenges in Implementing NFPA Standards

While NFPA standards are essential, implementing them can be challenging. Companies often face several obstacles, including:

- Complexity: NFPA standards are comprehensive and can be complex to understand and implement.

- Resource Intensive: Compliance requires significant resources, including time, money, and personnel.

- Continuous Monitoring: Ensuring ongoing compliance requires continuous monitoring and regular updates.

How FAT FINGER Digital Workflows Can Help

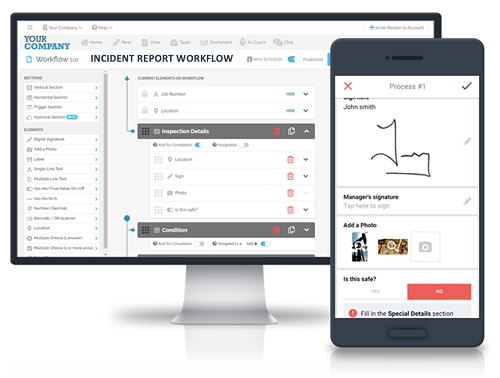

FAT FINGER offers a suite of digital workflows designed to simplify compliance with NFPA standards. These workflows provide a structured approach to safety management, making it easier to adhere to regulations and maintain a safe working environment.

Take 5 Safety

The Take 5 Safety checklist is a quick and effective tool for identifying hazards before starting a task. This checklist prompts workers to take five minutes to assess potential risks, ensuring they are aware of any hazards and can take appropriate precautions.

Near Miss Reporting

Near Miss Reporting is crucial for identifying and addressing potential hazards before they result in accidents. FAT FINGER’s Near Miss Reporting workflow allows workers to easily report near misses, ensuring that these incidents are documented and analyzed to prevent future occurrences.

Job Hazard Analysis

The Job Hazard Analysis (JHA) workflow helps identify potential hazards associated with specific tasks. This workflow guides workers through a systematic process of identifying risks and implementing control measures, ensuring that tasks are performed safely.

Risk Assessment

Risk Assessment is a critical component of safety management. FAT FINGER’s Risk Assessment workflow provides a structured approach to identifying and evaluating risks, ensuring that appropriate control measures are in place to mitigate them.

Incident Reporting in the Workplace

Incident Reporting is essential for documenting and analyzing accidents and incidents. FAT FINGER’s Incident Reporting workflow makes it easy to report incidents, ensuring that they are thoroughly investigated and that corrective actions are implemented to prevent recurrence.

Journey Report

The Journey Report workflow is designed to ensure the safety of workers during travel. This workflow prompts workers to document their journey, including any potential hazards they may encounter, ensuring that appropriate precautions are taken to ensure their safety.

Case Studies and Statistics

Several case studies highlight the effectiveness of NFPA standards and digital workflows in enhancing safety in the oil and gas industry. For example, a study by the American Petroleum Institute found that companies that implemented NFPA standards experienced a 30% reduction in accidents. Additionally, companies that used digital workflows like FAT FINGER reported a 25% increase in compliance with safety protocols.

Conclusion

Understanding and implementing NFPA standards is crucial for maintaining a safe working environment in the oil and gas industry. While compliance can be challenging, digital workflows like FAT FINGER provide a structured approach to safety management, making it easier to adhere to regulations and ensure the safety of personnel, equipment, and the environment.

By leveraging the power of digital workflows, companies can enhance their safety protocols, reduce risks, and ensure compliance with NFPA standards. To learn more about how FAT FINGER can help you achieve these goals, request a demo today.

Create a safety workflow for free on FAT FINGER or request a demo to see how our digital workflows can enhance your safety management processes.