Asset inspection in the oil and gas industry is a critical process that ensures the safety, efficiency, and longevity of operations. It involves the systematic examination of equipment and infrastructure to detect potential issues and prevent catastrophic failures. Digital solutions like FAT FINGER, make

the process of asset inspection has become more streamlined, accurate, and efficient. Request a demo today to see how FAT FINGER can revolutionize your asset inspection process.

The Importance of Asset Inspection in Oil and Gas

Asset inspection plays a pivotal role in the oil and gas industry for several reasons:

- Safety: Regular inspections help identify potential safety hazards, preventing accidents and ensuring the well-being of employees.

- Compliance: Inspections ensure that operations comply with industry regulations and standards, avoiding legal complications and penalties.

- Efficiency: By identifying and addressing issues early, inspections prevent costly downtime and enhance operational efficiency.

- Longevity: Regular maintenance, facilitated by inspections, extends the lifespan of assets, maximizing return on investment.

The Necessity of Digital Solutions in Asset Inspection

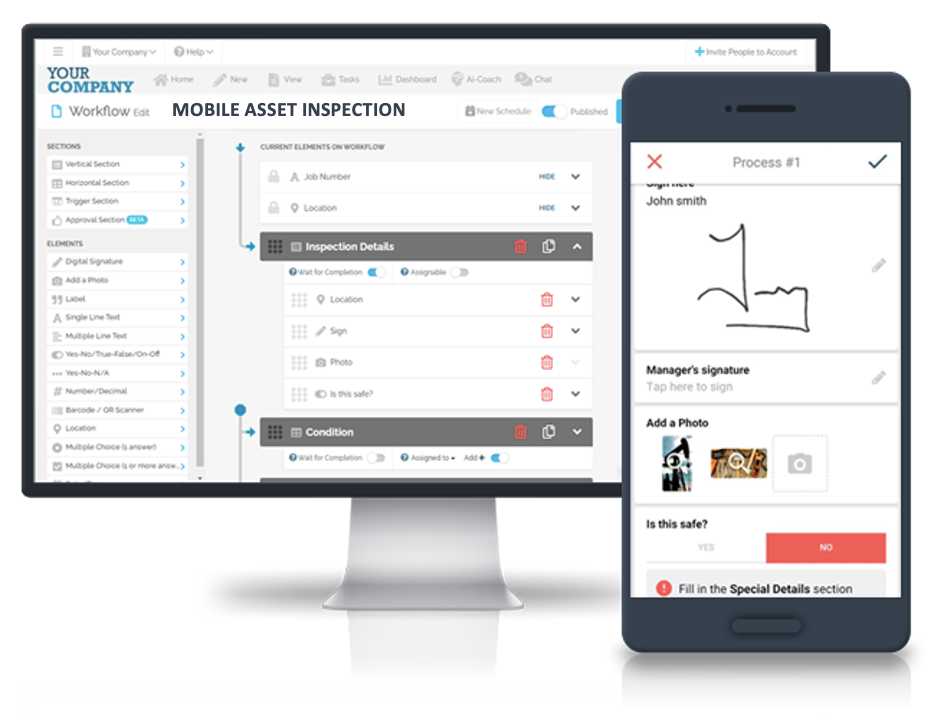

Traditional methods of asset inspection, involving manual data collection and paper-based reporting, are time-consuming, error-prone, and inefficient. This is where digital solutions like FAT FINGER come into play.

FAT FINGER’s mobile asset inspection workflows offer a host of benefits:

- Real-time data collection: With FAT FINGER, inspectors can collect and upload data in real-time, enabling immediate action on identified issues.

- Accuracy: Digital data collection minimizes human error, ensuring accurate and reliable inspection results.

- Efficiency: Automated workflows streamline the inspection process, saving time and resources.

- Compliance: FAT FINGER’s workflows are designed to meet industry standards, ensuring compliance with regulations.

Case Study: FAT FINGER in Action

A leading oil and gas company, struggling with inefficient and error-prone manual inspection processes, turned to FAT FINGER for a solution. By implementing FAT FINGER’s mobile asset inspection workflows, the company was able to streamline its inspection process, reduce errors, and improve compliance. As a result, the company saw a significant reduction in downtime, improved safety, and increased operational efficiency.

Conclusion: The Future of Asset Inspection is Digital

Asset inspection is a critical component of the oil and gas industry, ensuring safety, compliance, efficiency, and longevity of operations. The traditional methods of asset inspection, however, are no longer sufficient in today’s fast-paced, digital world. Digital solutions like FAT FINGER’s mobile asset inspection workflows offer a more efficient, accurate, and compliant alternative.

With real-time data collection, automated workflows, and compliance-focused design, FAT FINGER is revolutionizing the way asset inspections are conducted in the oil and gas industry. Don’t get left behind in the digital revolution. Create a mobile asset inspection workflow for free on FAT FINGER today and experience the future of asset inspection.