The oil and gas industry is a cornerstone of the global economy, providing essential energy resources. However, it is also one of the most hazardous industries, with significant risks to both human life and the environment. Effective asset inspection is crucial for ensuring the performance and safety of operations in this sector. This article delves into the importance of asset inspection, its impact on the industry, and how digital solutions like FAT FINGER can revolutionize the process. Request a demo to see how FAT FINGER can enhance your asset inspection workflows.

The Importance of Asset Inspection in the Oil and Gas Industry

Asset inspection involves the systematic examination of equipment, infrastructure, and facilities to ensure they are in optimal condition. In the oil and gas industry, this process is vital for several reasons:

- Safety: Regular inspections help identify potential hazards, preventing accidents and ensuring the safety of workers and the environment.

- Performance: Inspections ensure that equipment operates efficiently, reducing downtime and increasing productivity.

- Compliance: Adhering to regulatory standards is essential for avoiding legal penalties and maintaining a company’s reputation.

- Cost Savings: Early detection of issues can prevent costly repairs and extend the lifespan of assets.

Case Studies Highlighting the Impact of Asset Inspection

Several case studies illustrate the profound impact of effective asset inspection on the oil and gas industry:

Case Study 1: BP’s Prudhoe Bay Incident

In 2006, BP experienced a significant oil spill in Prudhoe Bay, Alaska, due to pipeline corrosion. The incident resulted in a loss of 267,000 gallons of oil and cost the company over $20 million in fines and cleanup expenses. An effective asset inspection program could have identified the corrosion early, preventing the spill and its associated costs.

Case Study 2: Shell’s Asset Integrity Management

Shell implemented a comprehensive asset integrity management program, which included regular inspections and maintenance. As a result, the company reported a 50% reduction in unplanned shutdowns and a 30% decrease in maintenance costs. This case demonstrates how proactive asset inspection can enhance operational efficiency and reduce expenses.

Challenges in Traditional Asset Inspection Methods

Despite its importance, traditional asset inspection methods face several challenges:

- Manual Processes: Traditional inspections often rely on manual data entry, which is time-consuming and prone to errors.

- Inconsistent Reporting: Different inspectors may use varying criteria, leading to inconsistent reporting and missed issues.

- Data Management: Storing and analyzing inspection data can be cumbersome, making it difficult to identify trends and areas for improvement.

- Limited Accessibility: Paper-based records are not easily accessible, hindering collaboration and decision-making.

How Digital Solutions Like FAT FINGER Address These Challenges

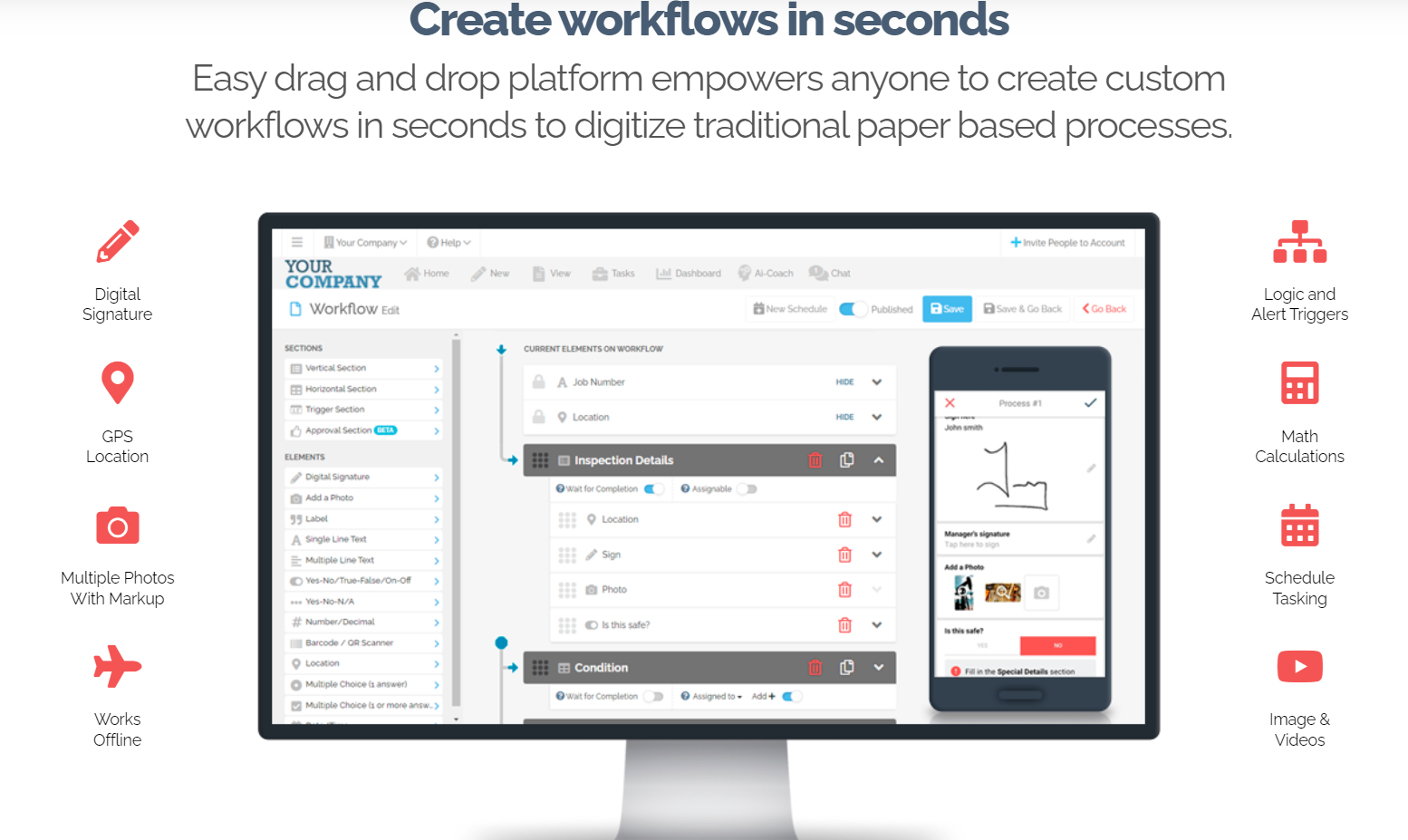

Digital solutions like FAT FINGER offer a modern approach to asset inspection, addressing the challenges of traditional methods:

- Automated Workflows: FAT FINGER automates inspection workflows, reducing the time and effort required for data entry.

- Standardized Reporting: The platform ensures consistent reporting by providing standardized inspection templates.

- Data Analytics: FAT FINGER’s data analytics capabilities enable companies to identify trends and areas for improvement, enhancing decision-making.

- Real-Time Access: Digital records are easily accessible, facilitating collaboration and ensuring that all stakeholders have the information they need.

Benefits of Using FAT FINGER for Asset Inspection

Implementing FAT FINGER for asset inspection offers numerous benefits:

- Enhanced Safety: By identifying potential hazards early, FAT FINGER helps prevent accidents and ensures a safer working environment.

- Improved Performance: The platform’s data analytics capabilities enable companies to optimize equipment performance and reduce downtime.

- Regulatory Compliance: FAT FINGER ensures that inspections adhere to regulatory standards, helping companies avoid legal penalties.

- Cost Savings: Early detection of issues through regular inspections can prevent costly repairs and extend the lifespan of assets.

Real-World Examples of FAT FINGER in Action

Several companies have successfully implemented FAT FINGER for asset inspection, achieving significant improvements in performance and safety:

Example 1: Offshore Drilling Company

An offshore drilling company used FAT FINGER to streamline its inspection processes. The platform’s automated workflows and standardized templates reduced inspection times by 40%, while its data analytics capabilities helped identify and address potential issues before they became critical.

Example 2: Refinery Operations

A refinery implemented FAT FINGER to enhance its asset inspection program. The platform’s real-time access to inspection data facilitated collaboration among teams, resulting in a 30% reduction in unplanned shutdowns and a 20% decrease in maintenance costs.

Conclusion

Effective asset inspection is crucial for ensuring the performance and safety of operations in the oil and gas industry. Traditional inspection methods face several challenges, including manual processes, inconsistent reporting, and data management issues. Digital solutions like FAT FINGER address these challenges by automating workflows, standardizing reporting, and providing real-time access to data.

By implementing FAT FINGER for asset inspection, companies can enhance safety, improve performance, ensure regulatory compliance, and achieve significant cost savings. To experience the benefits of FAT FINGER firsthand, create a mobile asset inspection workflow for free or request a demo today.