The oil and gas industry is fraught with potential hazards that can lead to catastrophic consequences if not properly managed. Implementing Hazard Analysis and Critical Control Points (HACCP) can significantly mitigate these risks.

This article delves into the importance of HACCP in the oil and gas sector, providing valuable insights and practical solutions. Request a demo of FAT FINGER to see how digital workflows can streamline your safety processes.

Understanding HACCP

HACCP is a systematic preventive approach to food safety, but its principles are equally applicable to other industries, including oil and gas. The primary goal of HACCP is to identify potential hazards and implement control measures to prevent accidents and ensure safety.

The Seven Principles of HACCP

- Conduct a hazard analysis

- Determine critical control points (CCPs)

- Establish critical limits

- Establish monitoring procedures

- Establish corrective actions

- Establish verification procedures

- Establish record-keeping and documentation procedures

These principles provide a structured framework for identifying and managing risks, making HACCP an invaluable tool for the oil and gas industry.

The Importance of HACCP in the Oil and Gas Industry

The oil and gas industry faces unique challenges that make the implementation of HACCP crucial. These challenges include:

- High-risk environments

- Complex operations

- Stringent regulatory requirements

- Potential for severe environmental impact

By implementing HACCP, companies can proactively address these challenges, ensuring the safety of their operations and compliance with regulations.

Case Study: BP Deepwater Horizon

The BP Deepwater Horizon disaster in 2010 serves as a stark reminder of the importance of effective risk management. The explosion resulted in 11 fatalities and a massive oil spill, causing significant environmental damage. A robust HACCP system could have identified the critical control points and implemented measures to prevent such a catastrophe.

Implementing HACCP: A Step-by-Step Guide

Implementing HACCP in the oil and gas industry involves several steps:

Step 1: Conduct a Hazard Analysis

Identify potential hazards associated with each stage of the operation. This includes physical, chemical, and biological hazards.

Step 2: Determine Critical Control Points (CCPs)

Identify points in the process where control measures can be applied to prevent or eliminate hazards.

Step 3: Establish Critical Limits

Set maximum and minimum limits for each CCP to ensure safety.

Step 4: Establish Monitoring Procedures

Develop procedures to monitor CCPs and ensure they remain within critical limits.

Step 5: Establish Corrective Actions

Define actions to be taken if a CCP deviates from its critical limits.

Step 6: Establish Verification Procedures

Implement procedures to verify that the HACCP system is working effectively.

Step 7: Establish Record-Keeping and Documentation Procedures

Maintain detailed records of all HACCP activities to ensure traceability and accountability.

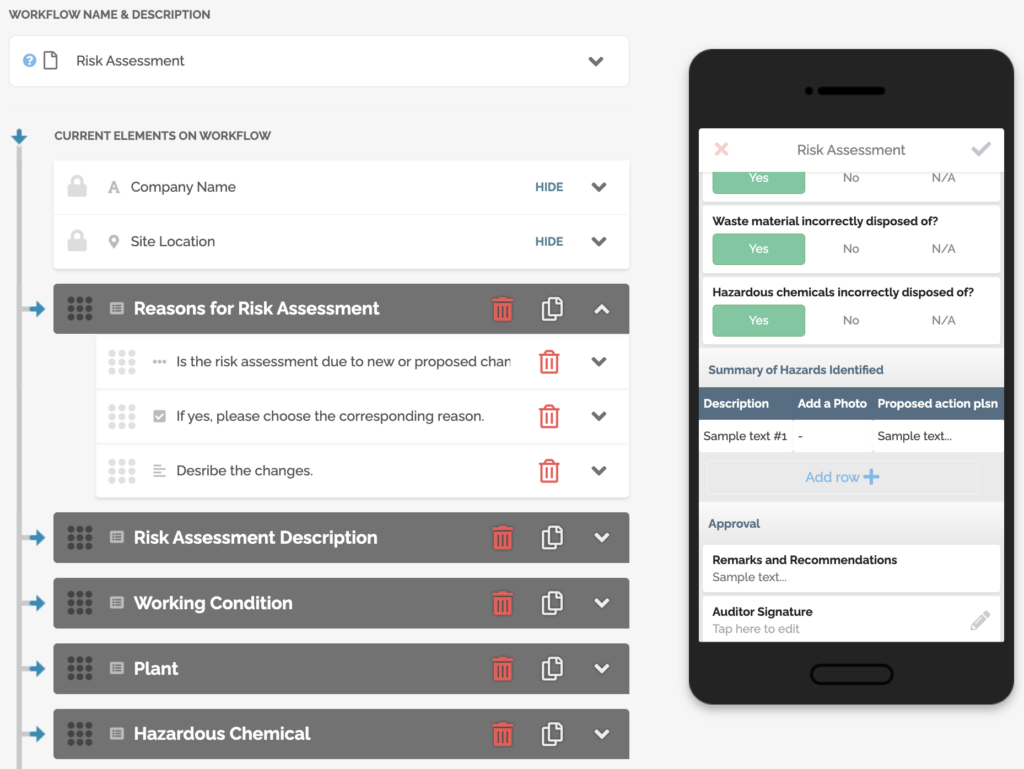

FAT FINGER: A Digital Solution for HACCP Implementation

Implementing HACCP can be a complex and time-consuming process. FAT FINGER offers a digital solution that simplifies and streamlines HACCP implementation through powerful safety checklists.

Take 5 Safety

The Take 5 Safety checklist helps workers quickly assess potential hazards before starting a task. This proactive approach ensures that risks are identified and mitigated early, enhancing overall safety.

Near Miss Reporting

Near Miss Reporting allows workers to report incidents that could have resulted in accidents. By analyzing these reports, companies can identify trends and implement preventive measures.

Job Hazard Analysis

The Job Hazard Analysis checklist helps identify potential hazards associated with specific tasks. This detailed analysis ensures that all risks are considered and appropriate control measures are implemented.

Risk Assessment

The Risk Assessment checklist provides a comprehensive evaluation of potential risks. This systematic approach ensures that all hazards are identified and managed effectively.

Incident Reporting in the Workplace

Incident Reporting in the Workplace allows for the detailed documentation of accidents and incidents. This information is crucial for identifying root causes and implementing corrective actions.

Journey Report

The Journey Report checklist helps monitor and manage risks associated with transportation and logistics. This ensures the safety of personnel and assets during transit.

Conclusion

Implementing HACCP in the oil and gas industry is essential for ensuring safety and compliance. The structured approach of HACCP helps identify and manage risks, preventing accidents and minimizing environmental impact. FAT FINGER offers a digital solution that simplifies HACCP implementation through powerful safety checklists. Create a safety workflow for free on FAT FINGER or request a demo to see how it can benefit your organization.

Create a safety workflow for free on FAT FINGER or request a demo.