Chemical processing industries are constantly seeking innovative solutions to enhance efficiency, safety, and productivity. One such solution is the use of real-time data applications, which can significantly improve operational processes. A leading player in this field is FAT FINGER, a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures that unlock operational excellence. This article will delve into how FAT FINGER’s features can enhance chemical processing through real-time data applications. If you’re interested in seeing how this works in action, feel free to schedule a demo.

Understanding FAT FINGER and Its Features

FAT FINGER is a software solution designed to streamline operations across various industries, including chemical processing. It offers a range of features that can be tailored to meet specific operational needs. These features include:

- Drag and drop workflow builder: This feature allows users to create and customize workflows easily, without the need for coding knowledge.

- Augmented reality: This feature enhances the user’s perception of the real-world environment, providing a more immersive experience.

- AI Coach: This feature provides real-time guidance and support to users, helping them to optimize their workflows.

- Connect to IoT devices: This feature allows users to connect their workflows to various IoT devices, enabling real-time data collection and analysis.

- Integrations: FAT FINGER can be integrated with various other software solutions, enhancing its functionality and versatility.

- mobile and desktop workflows: Users can access and manage their workflows from any device, ensuring seamless operations.

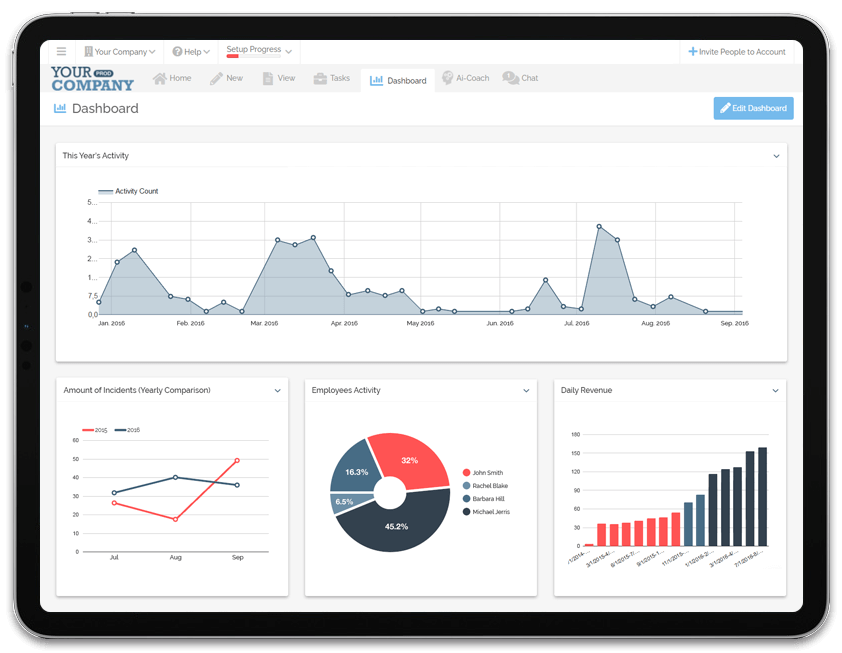

- Dashboards: These provide a visual representation of data, making it easier for users to understand and interpret information.

Enhancing Chemical Processing with FAT FINGER

Chemical processing involves complex procedures that require precision and accuracy. Real-time data applications created on FAT FINGER can significantly enhance these processes in several ways:

Real-Time Data Collection and Analysis

With FAT FINGER’s ability to connect to IoT devices, chemical processing industries can collect and analyze data in real-time. This allows for immediate detection of any anomalies or deviations from standard procedures, enabling prompt corrective action. This not only enhances efficiency but also significantly reduces the risk of costly errors or accidents.

Improved Workflow Management

The drag and drop workflow builder feature of FAT FINGER allows for the creation of customized workflows that suit the specific needs of the chemical processing industry. This ensures that all procedures are carried out systematically and accurately, enhancing productivity and operational efficiency.

Enhanced Safety Measures

Chemical processing involves handling hazardous substances, making safety a top priority. FAT FINGER’s real-time data applications can help monitor safety parameters and alert personnel to any potential risks, thereby enhancing safety measures.

Case Study: Real-Time Data Application in Chemical Processing

A leading chemical processing company implemented FAT FINGER’s real-time data applications in its operations. The company was able to monitor its processes in real-time, enabling immediate detection and correction of any deviations.

This resulted in a significant reduction in errors and accidents, leading to improved safety and efficiency. The company also reported a significant increase in productivity, thanks to the improved workflow management provided by FAT FINGER.

Conclusion

Real-time data applications created on FAT FINGER can significantly enhance chemical processing operations. By providing real-time data collection and analysis, improved workflow management, and enhanced safety measures, FAT FINGER helps chemical processing industries achieve operational excellence. If you’re interested in leveraging these benefits for your operations, you can build a digital workflow for free on FAT FINGER or schedule a demo to see how it works.