In the world of asset management, determining the appropriate frequency for asset inspections is crucial. Regular inspections ensure that assets are functioning optimally, reduce downtime, and prevent costly repairs. However, finding the right balance between too frequent and too infrequent inspections can be challenging. This article delves into the factors influencing inspection frequency and offers insights into optimizing your inspection schedule. For a more efficient inspection process, consider requesting a demo of FAT FINGER’s digital workflows.

Understanding the Importance of Asset Inspections

Asset inspections are vital for maintaining the longevity and efficiency of equipment and infrastructure. Regular inspections help identify potential issues before they escalate into major problems. This proactive approach can save organizations significant time and money.

Benefits of Regular Inspections

- Early detection of wear and tear

- Prevention of unexpected breakdowns

- Compliance with safety regulations

- Extended asset lifespan

- Improved operational efficiency

Given these benefits, it’s clear that regular inspections are essential. However, the challenge lies in determining the optimal frequency for these inspections.

Factors Influencing Inspection Frequency

Several factors influence how often assets should be inspected. Understanding these factors can help organizations develop a tailored inspection schedule that meets their specific needs.

1. Asset Type and Usage

The type of asset and its usage play a significant role in determining inspection frequency. For example, high-use machinery may require more frequent inspections than equipment used less often. Similarly, critical assets that are essential to operations may need more regular checks.

2. Manufacturer Recommendations

Manufacturers often provide guidelines on how frequently their equipment should be inspected. These recommendations are based on extensive testing and can serve as a valuable starting point for developing an inspection schedule.

3. Environmental Conditions

The environment in which an asset operates can impact its inspection frequency. Harsh conditions, such as extreme temperatures or corrosive environments, may necessitate more frequent inspections to ensure the asset remains in good condition.

4. Historical Data and Performance Trends

Analyzing historical data and performance trends can provide insights into how often an asset should be inspected. If an asset has a history of frequent issues, it may require more regular inspections.

5. Regulatory Requirements

Compliance with industry regulations and standards is another critical factor. Some industries have specific requirements for inspection frequency to ensure safety and reliability.

Case Studies: Real-World Examples

To illustrate the importance of determining the appropriate inspection frequency, let’s look at a few real-world examples.

Case Study 1: Manufacturing Plant

A manufacturing plant experienced frequent machinery breakdowns, leading to costly downtime. By analyzing historical data, the plant identified that certain machines required more frequent inspections. Implementing a tailored inspection schedule reduced breakdowns by 30% and improved overall efficiency.

Case Study 2: Transportation Company

A transportation company faced challenges with vehicle maintenance. By following manufacturer recommendations and considering environmental conditions, the company developed an optimized inspection schedule. This proactive approach reduced maintenance costs by 20% and increased vehicle reliability.

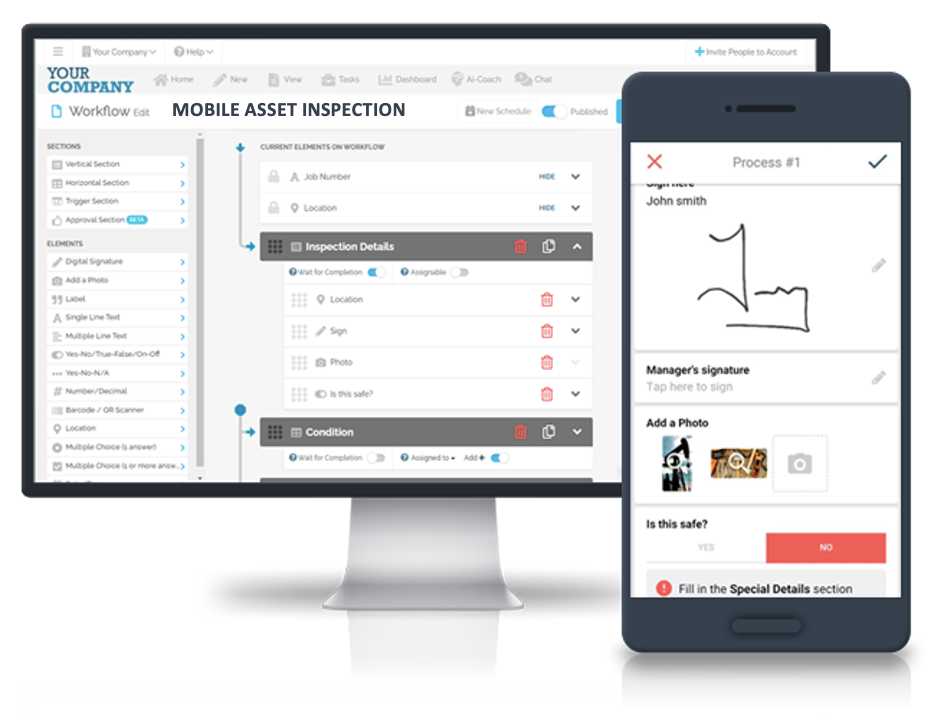

Optimizing Inspection Frequency with Digital Workflows

Determining the appropriate inspection frequency is just the first step. Implementing and managing an effective inspection schedule can be complex. This is where digital workflows, like those offered by FAT FINGER, come into play.

Streamlining the Inspection Process

FAT FINGER’s digital workflows streamline the inspection process by providing a centralized platform for scheduling, conducting, and tracking inspections. This ensures that inspections are carried out consistently and on time.

Data-Driven Insights

With FAT FINGER, organizations can leverage data-driven insights to optimize their inspection schedules. The platform collects and analyzes data from inspections, helping identify trends and areas for improvement.

Customizable Inspection Checklists

FAT FINGER allows organizations to create customizable inspection checklists tailored to their specific needs. This ensures that all critical aspects of an asset are inspected, reducing the risk of overlooking potential issues.

Real-Time Reporting and Alerts

Real-time reporting and alerts keep stakeholders informed about the status of inspections. This proactive approach enables quick action to address any identified issues, minimizing downtime and maintaining asset performance.

Conclusion

Determining the appropriate frequency for asset inspections is essential for maintaining operational efficiency and reducing costs. By considering factors such as asset type, usage, environmental conditions, and historical data, organizations can develop tailored inspection schedules. Digital workflows, like those offered by FAT FINGER, can further optimize the inspection process, providing data-driven insights and real-time reporting.

For a more efficient and effective inspection process, consider creating a mobile asset inspection workflow for free on FAT FINGER or request a demo today.