The oil and gas industry is a complex and multifaceted sector that requires meticulous planning, execution, and safety measures. One of the critical components in this industry is the Construction, Procurement, and Production (CPP) process. Understanding CPP is essential for ensuring efficient operations, minimizing risks, and maximizing productivity.

In this article, we will delve into the intricacies of CPP, explore its significance, and highlight how digital workflows like FAT FINGER can streamline these processes.

Request a demo today to see how FAT FINGER can revolutionize your CPP operations.

Understanding CPP: Construction, Procurement, and Production

CPP stands for Construction, Procurement, and Production, which are three fundamental phases in the oil and gas industry. Each phase plays a crucial role in the lifecycle of oil and gas projects, from initial planning to final production.

Construction

Construction involves the physical building of infrastructure, such as drilling rigs, pipelines, and refineries. This phase requires meticulous planning, skilled labor, and adherence to safety standards. Delays or errors in construction can lead to significant financial losses and safety hazards.

Procurement

Procurement is the process of acquiring the necessary materials, equipment, and services required for construction and production. Effective procurement ensures that projects stay on schedule and within budget. It involves supplier selection, contract management, and logistics coordination.

Production

Production is the phase where oil and gas are extracted, processed, and transported to end-users. This phase requires continuous monitoring, maintenance, and optimization to ensure efficient and safe operations. Production efficiency directly impacts profitability and sustainability.

The Importance of CPP in the Oil and Gas Industry

CPP is vital for the success of oil and gas projects. It ensures that projects are completed on time, within budget, and to the required quality standards. Here are some key reasons why CPP is essential:

- Cost Management: Effective CPP processes help control costs by minimizing delays, reducing waste, and optimizing resource utilization.

- Risk Mitigation: Proper planning and execution of CPP phases reduce the risk of accidents, equipment failures, and environmental incidents.

- Quality Assurance: Adhering to CPP standards ensures that infrastructure and equipment meet industry regulations and quality benchmarks.

- Operational Efficiency: Streamlined CPP processes enhance productivity and operational efficiency, leading to higher profitability.

Challenges in CPP and the Need for Digital Workflows

Despite its importance, CPP processes face several challenges that can hinder project success. These challenges include:

- Complex Coordination: Coordinating multiple stakeholders, suppliers, and contractors can be challenging and time-consuming.

- Data Management: Managing vast amounts of data, including project plans, procurement records, and production metrics, can be overwhelming.

- Safety Compliance: Ensuring compliance with safety regulations and standards is critical but can be difficult to monitor and enforce.

- Risk Management: Identifying and mitigating risks throughout the CPP phases requires continuous monitoring and proactive measures.

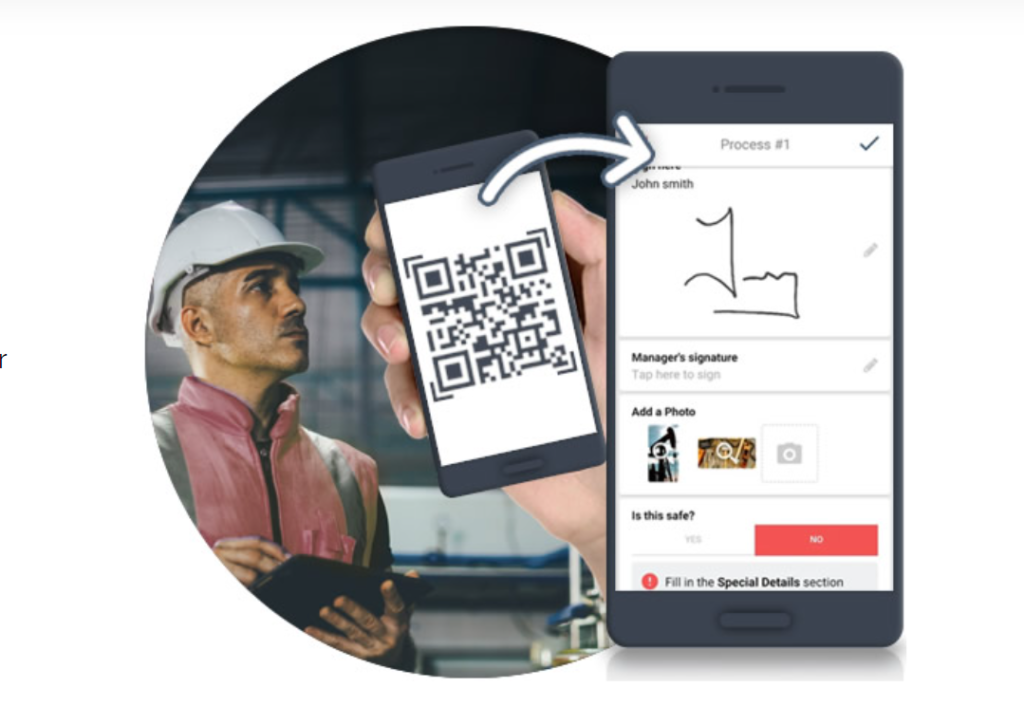

To address these challenges, digital workflows like FAT FINGER offer a comprehensive solution. FAT FINGER provides powerful safety checklists and digital tools that streamline CPP processes, enhance safety compliance, and improve overall efficiency.

How FAT FINGER Enhances CPP Processes

FAT FINGER is a digital workflow platform designed to simplify and optimize CPP processes in the oil and gas industry. Here are six powerful safety checklists offered by FAT FINGER that can revolutionize your CPP operations:

1. Take 5 Safety

The Take 5 Safety checklist encourages workers to take five minutes before starting a task to assess potential hazards and ensure safety measures are in place. This proactive approach reduces the risk of accidents and promotes a safety-first culture.

2. Near Miss Reporting

Near Miss Reporting allows workers to report incidents that could have resulted in accidents but did not. By analyzing near misses, organizations can identify patterns, implement corrective actions, and prevent future incidents.

3. Job Hazard Analysis

The Job Hazard Analysis checklist helps identify potential hazards associated with specific tasks and outlines preventive measures. This ensures that workers are aware of risks and equipped to handle them safely.

4. Risk Assessment

Risk Assessment involves evaluating potential risks in CPP processes and implementing strategies to mitigate them. FAT FINGER’s digital tools enable real-time risk assessment and monitoring, ensuring proactive risk management.

5. Incident Reporting in the Workplace

Incident Reporting in the Workplace allows for the quick and efficient reporting of accidents, injuries, and other incidents. This ensures timely investigation, corrective actions, and compliance with safety regulations.

6. Journey Report

The Journey Report checklist tracks the movement of personnel and equipment, ensuring safe and efficient transportation. This is particularly important in remote and hazardous locations where transportation risks are high.

Conclusion: Streamline Your CPP Processes with FAT FINGER

In conclusion, CPP is a critical component of the oil and gas industry, encompassing construction, procurement, and production phases. Effective CPP processes are essential for cost management, risk mitigation, quality assurance, and operational efficiency. However, these processes face several challenges that can hinder project success.

Digital workflows like FAT FINGER offer a comprehensive solution to these challenges. With powerful safety checklists such as Take 5 Safety, Near Miss Reporting, Job Hazard Analysis, Risk Assessment, Incident Reporting in the Workplace, and Journey Report, FAT FINGER streamlines CPP processes, enhances safety compliance, and improves overall efficiency.

Don’t let CPP challenges hold you back. Create a safety workflow for free on FAT FINGER or request a demo today to see how FAT FINGER can revolutionize your CPP operations.