Key Takeaways

- Understanding APM: Recognize the importance of APM in improving asset reliability and availability in the oil industry.

- Implementing Safety Measures: Use condition monitoring, predictive maintenance, risk management, and performance optimization to enhance safety and efficiency.

- Utilizing Digital Solutions: Leverage FAT FINGER’s digital workflows for real-time data collection, predictive analytics, and mobile accessibility.

- Proactive Maintenance: Identify and address potential asset failures before they occur to reduce downtime and maintenance costs.

- Compliance and Safety: Ensure compliance with industry regulations and enhance safety by using advanced APM techniques.

What is APM In The Oil Industry?

The oil industry is a complex and high-stakes sector where efficiency, safety, and reliability are paramount. One of the key strategies employed to achieve these goals is asset performance management (APM). In this article, we will delve into what APM is, its importance in the oil industry, and how digital solutions like FAT FINGER can revolutionize APM practices. If you’re looking to optimize your asset management, request a demo today.

Understanding Asset Performance Management (APM)

Asset performance management (APM) is a set of processes and technologies aimed at improving the reliability and availability of physical assets. In the oil industry, these assets include drilling rigs, pipelines, refineries, and other critical infrastructure. APM involves monitoring, analyzing, and optimizing the performance of these assets to ensure they operate efficiently and safely.

Key Components of APM

APM encompasses several key components:

- Condition Monitoring: Continuous tracking of asset health using sensors and data analytics.

- Predictive Maintenance: Using data to predict when an asset will fail and performing maintenance before it happens.

- Risk Management: Identifying and mitigating risks associated with asset failure.

- Performance Optimization: Enhancing asset performance through data-driven insights.

The Importance of APM in the Oil Industry

The oil industry faces numerous challenges, including fluctuating oil prices, stringent regulatory requirements, and the need for operational efficiency. APM plays a crucial role in addressing these challenges by:

- Reducing Downtime: Predictive maintenance helps prevent unexpected failures, reducing costly downtime.

- Enhancing Safety: Monitoring asset health ensures that potential issues are identified and addressed before they become safety hazards.

- Optimizing Costs: Efficient asset management reduces maintenance costs and extends asset life.

- Compliance: APM helps ensure compliance with industry regulations and standards.

Case Studies: APM in Action

To illustrate the impact of APM, let’s look at a couple of real-world examples:

Case Study 1: Offshore Drilling Rig

An offshore drilling company implemented an APM solution to monitor the health of its drilling rigs. By using predictive analytics, the company was able to identify potential equipment failures before they occurred. This proactive approach reduced unplanned downtime by 30% and saved millions in maintenance costs.

Case Study 2: Refinery Operations

A large refinery adopted APM to optimize its operations. By continuously monitoring equipment performance and using data analytics, the refinery improved its overall efficiency by 15%. This not only reduced operational costs but also enhanced safety by identifying and mitigating risks in real-time.

The Role of Digital Workflows in APM

Digital workflows are transforming the way APM is implemented in the oil industry. Traditional methods of asset management often involve manual processes, which can be time-consuming and prone to errors. Digital workflows streamline these processes, making APM more efficient and effective.

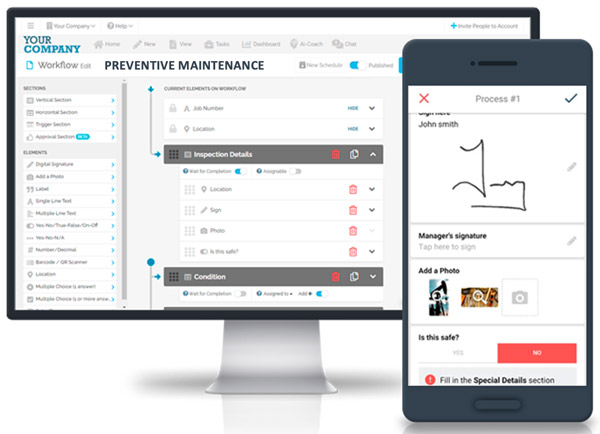

Introducing FAT FINGER

FAT FINGER is a leading digital workflow solution designed to enhance APM practices. It offers a range of features that address the pain points of traditional asset management:

- Real-Time Data Collection: FAT FINGER enables real-time data collection from assets, providing accurate and up-to-date information on asset health.

- Predictive Analytics: The platform uses advanced analytics to predict potential failures and recommend maintenance actions.

- Risk Management: FAT FINGER helps identify and mitigate risks by providing insights into asset performance and potential issues.

- Mobile Accessibility: With FAT FINGER, asset management can be performed on-the-go using mobile devices, ensuring that critical information is always at your fingertips.

How FAT FINGER Solves APM Challenges

Let’s explore how FAT FINGER addresses specific APM challenges in the oil industry:

Challenge 1: Unplanned Downtime

Unplanned downtime can be costly and disruptive. FAT FINGER’s predictive analytics capabilities help identify potential failures before they occur, allowing for timely maintenance and reducing downtime.

Challenge 2: Safety Risks

Safety is a top priority in the oil industry. FAT FINGER’s real-time data collection and risk management features ensure that potential safety hazards are identified and addressed promptly, enhancing overall safety.

Challenge 3: High Maintenance Costs

Maintenance costs can quickly add up. By optimizing maintenance schedules and performing predictive maintenance, FAT FINGER helps reduce maintenance costs and extend the life of assets.

Challenge 4: Compliance

Compliance with industry regulations is essential. FAT FINGER’s digital workflows ensure that all maintenance activities are documented and compliant with regulatory requirements, reducing the risk of non-compliance.

Conclusion

Asset performance management (APM) is a critical strategy for optimizing the performance, safety, and reliability of assets in the oil industry. By leveraging digital workflows like FAT FINGER, companies can overcome the challenges of traditional asset management and achieve significant improvements in efficiency, safety, and cost savings.

If you’re ready to revolutionize your asset management practices, create a mobile asset inspection workflow for free on FAT FINGER or request a demo today. Experience the benefits of digital workflows and take your APM to the next level.

FAQs About Asset Performance Management (APM)

Q: What is Asset Performance Management (APM)?

APM is a set of processes and technologies aimed at improving the reliability and availability of physical assets, such as drilling rigs, pipelines, and refineries in the oil industry. It involves monitoring, analyzing, and optimizing asset performance to ensure efficiency and safety.

Q: Why is APM important in the oil industry?

APM is crucial for reducing downtime, enhancing safety, optimizing costs, and ensuring compliance with industry regulations. It helps address challenges such as fluctuating oil prices, stringent regulatory requirements, and the need for operational efficiency.

Q: What are the key components of APM?

- Condition Monitoring: Continuous tracking of asset health using sensors and data analytics.

- Predictive Maintenance: Using data to predict asset failures and perform maintenance proactively.

- Risk Management: Identifying and mitigating risks associated with asset failure.

- Performance Optimization: Enhancing asset performance through data-driven insights.

Q: How can digital workflows like FAT FINGER help with APM?

FAT FINGER offers real-time data collection, predictive analytics, risk management, and mobile accessibility. These features streamline APM processes, making them more efficient and effective.

Q: Can you provide examples of APM in action?

- Offshore Drilling Rig: Implemented APM to monitor drilling rigs, reducing unplanned downtime by 30% and saving millions in maintenance costs.

- Refinery Operations: Adopted APM to optimize operations, improving efficiency by 15% and enhancing safety.

Q: How can I implement FAT FINGER in my workplace?

Request a demo through the FAT FINGER website to see how our digital workflows can enhance asset performance management practices.

Q: What are the main benefits of using FAT FINGER for APM?

FAT FINGER improves operational efficiency, reduces unplanned downtime, enhances safety, and ensures compliance with industry regulations through real-time data collection, predictive analytics, and risk management.

Q: How does FAT FINGER support mobile accessibility?

FAT FINGER’s mobile-friendly platform allows workers to access and input data from anywhere, ensuring that asset performance management processes are seamless and efficient even in remote locations.