Key Takeaways

- Regular rig tool maintenance prevents costly breakdowns and extends tool life.

- Daily inspections and proper cleaning are essential to avoid equipment failures.

- Preventive measures like lubrication and corrosion protection are key in harsh environments.

- Using FAT FINGER can help automate and streamline your maintenance process.

- Well-maintained rig tools improve safety, efficiency, and reduce operational downtime.

The Ultimate Guide to Rig Tool Maintenance

If you’re responsible for rig tools, you already know that keeping them in top shape is critical to avoiding downtime, costly repairs, and potential safety hazards. Rig tools endure harsh conditions, making regular maintenance essential for maintaining their performance.

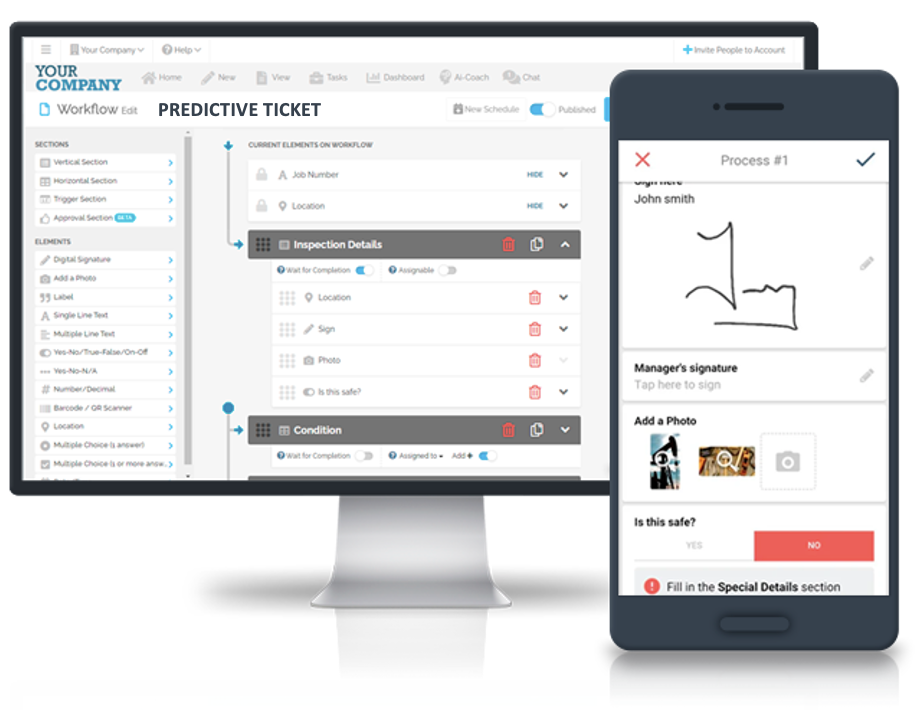

This guide will walk you through the best practices for keeping your rig tools in peak condition, from daily care to advanced maintenance strategies. We’ll also explore how FAT FINGER, a digital workflow builder, can help you automate your maintenance efforts, making the whole process more efficient.

Types of Maintenance for Rig Tools

To keep your rig tools operating smoothly, it’s essential to understand the different types of maintenance:

- Preventive Maintenance: This involves regularly scheduled inspections, cleaning, and part replacements before failure occurs. It’s your first line of defense against unexpected issues.

- Predictive Maintenance: By monitoring data, you can anticipate when a tool will need maintenance based on its usage and performance. This approach allows you to address issues just in time, reducing downtime.

- Reactive Maintenance: This is maintenance performed after a breakdown. While necessary at times, relying too much on reactive maintenance can lead to costly delays and repairs. A balanced maintenance strategy that emphasizes preventive and predictive maintenance can drastically reduce your reliance on reactive measures, helping you maintain optimal productivity.

4 Step Maintenance Plan For An Oil Rig

Step 1- Daily Inspection and Cleaning Procedures

A good maintenance plan starts with daily care. Each day before using your tools, inspect them for any signs of damage or wear—loose components, cracks, or dull cutting edges can signal that it’s time for maintenance.

After using your tools, take a few minutes to clean them thoroughly. Dirt, grease, and debris can cause wear and corrosion over time, so a quick cleaning session after each job helps preserve the life of your tools. Make this part of your routine, and you’ll notice fewer unexpected failures.

Step 2 – Lubrication and Corrosion Prevention

Your rig tools are exposed to harsh conditions, from moisture and dirt to extreme temperatures. One of the best ways to protect them is by using the right lubrication and corrosion prevention techniques. Lubricating moving parts reduces friction and wear, while anti-corrosion treatments help prevent rust, especially on tools exposed to the elements.

Be sure to select lubricants and protective coatings that are suited to the specific tools you’re using. This small step can greatly extend the life of your equipment.

Step 3 – Sharpening and Reconditioning Rig Tools

Rig tools that involve cutting or drilling can lose their edge over time, which not only reduces efficiency but can also cause safety issues. Regularly sharpening and reconditioning tools like blades and bits will ensure they perform at their best.

Don’t wait until they become blunt or damaged—schedule regular sharpening based on usage to keep them in top condition. Additionally, reconditioning worn-out tools can give them a second life, saving you from having to purchase replacements.

Step 4 – Proper Storage Techniques for Rig Tools

Storing your rig tools properly is just as important as maintaining them. Tools that are left out in the open or stored incorrectly can get damaged easily, leading to reduced performance and a shorter lifespan.

Make sure you organize your tools in proper storage units, such as toolboxes or shelves, that keep them protected from dust, moisture, and accidental impacts.

For more delicate tools, consider using cases or padded storage. Proper storage not only protects your investment but also ensures that tools are easy to find and ready to use when needed.

12 Best Practices for Maintaining Rig Tools

- Conduct daily inspections: Before each use, check for any visible signs of wear, damage, or malfunction. This helps catch potential issues before they escalate.

- Clean tools after every use: Proper cleaning removes dirt, grease, and other contaminants that can cause corrosion or damage over time.

- Lubricate moving parts regularly: Using the right lubricant reduces friction, prevents wear, and helps protect against rust.

- Follow manufacturer guidelines: Always refer to the manufacturer’s maintenance recommendations to ensure proper care.

- Sharpen cutting tools frequently: Keeping blades and bits sharp improves efficiency and reduces the risk of accidents caused by dull tools.

- Store tools properly: Use toolboxes, shelves, or cases to protect tools from environmental damage and accidental wear.

- Inspect and replace worn parts: If a part is showing signs of excessive wear, replace it immediately to avoid larger issues down the line. Build an asset inspection workflow

- Use tools as intended: Avoid using tools in ways that exceed their intended purpose, as this can cause premature wear or damage.

- Train personnel in proper tool care: Ensure everyone handling rig tools is trained in basic maintenance and safe handling practices.

- Maintain a maintenance log: Keep detailed records of inspections, repairs, and maintenance activities for each tool.

- Schedule regular reconditioning: When tools start to lose their functionality, reconditioning can restore their performance.

- Automate maintenance tracking: Use digital tools like FAT FINGER to automate maintenance schedules, set reminders, and track performance metrics.

Safety Precautions During Rig Tool Maintenance

Safety should always be a top priority when maintaining rig tools.

- Before performing any maintenance tasks, make sure you and your team are equipped with the right personal protective equipment (PPE), such as gloves, goggles, or helmets.

- Be cautious when handling sharp tools or heavy equipment

- Never attempt repairs without first ensuring that the tool is powered off and properly secured.

Safety procedures are just as important as maintenance to ensure your team stays safe and the job is done right.

Training and Best Practices for Rig Tool Maintenance

Proper training is essential for anyone involved in rig tool maintenance. Your team should know how to inspect, clean, and store tools, as well as how to handle them safely. Implement a regular training program that covers both the basics and more advanced maintenance techniques. This ensures consistency in how your tools are cared for and helps prevent mistakes.

Additionally, using digital tools like FAT FINGER can simplify the process, allowing you to track maintenance schedules, automate reminders, and maintain an organized system for tool care.

Common Mistakes to Avoid in Rig Tool Care

- Skipping routine inspections: Ignoring daily checks can lead to undetected issues and bigger problems.

- Using incorrect lubricants or cleaning agents: This can damage tools instead of protecting them.

- Delaying repairs or part replacements: Waiting too long to fix or replace worn parts can lead to larger, costlier failures.

- Improper storage: Leaving tools exposed to the elements or storing them improperly can reduce their lifespan significantly.

Conclusion

Maintaining your rig tools is about more than just keeping them operational—it’s about improving efficiency, reducing downtime, and ensuring safety. By following these best practices, you can extend the life of your equipment and create a more productive work environment. And by leveraging tools like FAT FINGER to automate maintenance tasks, you can streamline the entire process, making it easier to stay on top of your maintenance plan.

FAQs About Maintenance of Oil Rig Tools

Q: Why is preventive maintenance important for rig tools?

Preventive maintenance helps identify and address issues before they cause equipment failure, reducing downtime and repair costs.

Q: How often should I inspect my rig tools?

Rig tools should be inspected daily before use to check for any signs of wear, damage, or malfunction.

Q: What are the benefits of using FAT FINGER for maintenance tracking?

FAT FINGER helps automate maintenance tasks, track performance data, and set reminders, improving efficiency and consistency in your maintenance plan.

Q: How do I prevent corrosion on rig tools in harsh environments?

Regularly applying anti-corrosion treatments and using proper storage techniques can help protect your tools from rust and corrosion.

Q: What are the most common mistakes in rig tool maintenance?

Common mistakes include skipping inspections, using improper lubricants, delaying repairs, and improper storage.